Walnuts for Ice Cream and Frozen Desserts: Texture and Freeze/Thaw Considerations

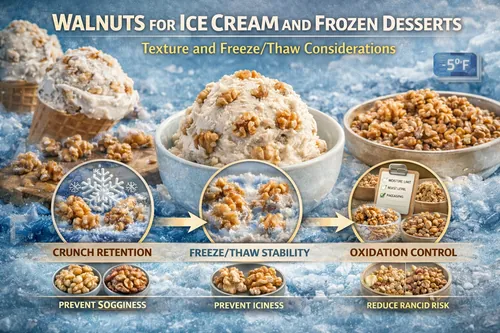

Industrial guide for walnuts in frozen systems—how walnut format, piece size, and inclusion preparation impact crunch retention, flavor stability, and consumer texture across freeze/thaw and temperature-cycling conditions. Includes spec checkpoints, packaging options, and buyer documentation for bulk walnut programs.

Previous: Walnuts in Sauces (Pesto-Style, Romesco-Style): Emulsions and Heat Stability • Next: In-Shell Walnuts (Natural vs Bleached): Market Preferences and Handling Notes

Related: bulk walnut products • products catalog • request a quote

Where walnuts fit in frozen dessert production

Walnuts are used as inclusions and toppings in ice cream, gelato, frozen yogurt, novelties, and frozen dessert mixes. The format decision usually comes down to texture retention and distribution consistency: you want the nut to stay pleasant to bite while remaining stable through your cold chain.

- Mix-ins (variegate or direct inclusion): controlled pieces to avoid sink/float segregation and to fit depositor geometry.

- Toppings: larger pieces for visual impact; tighter defect and color limits matter more.

- Swirls / paste systems: walnut paste or meal for flavor; higher surface area increases oxidation sensitivity.

If your product sees frequent temperature cycling (retail freezers, door openings, long distribution lanes), prioritize inclusion prep and packaging that protect texture and flavor.

Freeze/thaw and temperature cycling: what changes walnuts

In frozen desserts, walnuts don’t usually “freeze-thaw” like a high-water ingredient, but they can still change texture and flavor as the surrounding matrix partially melts and refreezes at the inclusion surface. The main risks are:

1) Softening from moisture migration

Even at frozen temperatures, localized melting at the nut interface during temperature cycling can introduce moisture that dulls crunch over time. Smaller cuts soften faster because they have higher surface area.

2) Ice crystal pickup and “wet” bite

Rough surfaces, excess fines, and irregular piece geometry can create more surface sites for ice to cling. This can read as a frosty or wet bite, especially in products that experience repeated cycling.

3) Oxidation (rancid notes) despite freezing

Freezing slows oxidation but doesn’t stop it completely. Oxygen exposure, prior heat exposure (e.g., roasted nuts handled warm), and long storage windows increase risk. Good barrier packaging and controlled storage still matter.

Format selection: matching piece size to texture and line performance

The “best” cut is the one that delivers the target crunch and distribution without stressing your equipment or consumer bite. Consider:

- Large pieces / halves: premium look and bite; more fragile (breakage creates fines) and more variable in distribution.

- Controlled pieces: best for uniformity and depositor flow; typically the most forgiving choice at scale.

- Fine pieces / meal: best for flavor dispersion; highest oxidation sensitivity and fastest texture change.

Practical note: if you see “muddy” inclusions or excessive thickening in inclusion prep, dust/fines and surface oil management are usually the first things to review.

Inclusion preparation strategies that improve crunch retention

Roast profile (if applicable)

Roasting can boost flavor and reduce perceived astringency, but it can also increase oxidation sensitivity if not managed. If you buy roasted walnuts, define the roast level and confirm sensory targets and shelf-life expectations for frozen storage.

Coatings and barriers (often used in frozen)

Coated or candied inclusions are common in frozen desserts because coatings can reduce moisture pickup and keep inclusions crisp longer. The best option depends on sweetness target, labeling constraints, and whether you need clean “nut-only” statements.

Managing fines and dust

Fines can disperse into the matrix, create gritty mouthfeel, and increase ice pickup at inclusion interfaces. If you want a cleaner bite, specify a fines tolerance and minimize mechanical abuse during receiving and pre-blending.

Format and spec checkpoints buyers should confirm (frozen-dessert focused)

Typical checkpoints include moisture, size/cut specification, defect and color limits, roast profile (if applicable), and microbiological requirements for your category. Frozen dessert programs often add:

- Cut/size tolerance: improves uniform inclusion distribution and consumer bite comfort.

- Fines/dusting level: reduces gritty mouthfeel and process losses.

- Oxidation posture: align on sensory and storage guidance for long frozen shelf life.

- Foreign material controls: critical for consumer safety and complaint prevention.

- Micro requirements: set targets consistent with your process and whether there is any kill step downstream.

Processing and shelf-life considerations

Walnuts are oxidation sensitive. Oxygen exposure, heat, and light can reduce shelf life. For frozen desserts, the biggest “silent” risk is temperature cycling in distribution and retail. If your product will see variable freezer conditions, choose more conservative specs and packaging.

Packaging options for bulk programs

Bulk programs commonly use lined bags/cartons for kernels and cuts, sealed bulk bags for meal/flour, and drums or totes for oils and butters. For frozen dessert inclusions, packaging should match your hold time and oxygen control needs.

- Pieces / kernels: lined cartons or bags; consider higher-barrier liners for long storage windows.

- Meal / fine cuts: tighter seals and oxygen control matter more because surface area is higher.

- Roasted formats: confirm whether the supplier recommends different packaging or storage constraints.

Share receiving constraints (dock schedule, frozen storage availability, repack needs, pallet configuration) early to avoid delays.

How to request a quote with fewer back-and-forths

Send: product + format (pieces/halves/meal), target cut size and fines tolerance, raw vs roasted (and roast level if applicable), defect/color limits, micro requirements, packaging preference, first order volume, annual forecast, destination, and timeline. If you have a spec sheet, include it—this is the fastest path to an accurate offer.

Next step

If you share your frozen application (ice cream/gelato/frozen yogurt/novelty), target inclusion size, inclusion rate, and your distribution/storage conditions, we can confirm common spec targets and packaging options that support crunch retention. Use Request a Quote or email info@almondsandwalnuts.com.