Specifying Defects and Color for Walnut Kernels: Buyer Checklist

Industrial buyer checklist for walnut kernels: how to specify defect limits and color expectations to protect yield, line performance, and shelf-life stability. Includes spec and COA fields, receiving inspection checklist, packaging notes, and supplier questions for bulk walnut programs.

Previous: Export Programs for Walnuts: Moisture, Sorting, and Documentation Basics • Next: Managing Oxidation in Walnuts: Storage Temperature, Oxygen, and Light

Related: bulk walnut products • products catalog • request a quote

Why defect and color specs matter in bulk walnut programs

In industrial buying, your spec is a way to buy predictable line performance, predictable edible yield, and predictable shelf-life behavior. Walnut kernels are naturally high in oil. That oil is valuable (flavor, nutrition, richness), but it also means walnuts can show oxidation drift faster than many low-fat ingredients when lots are stressed by heat, oxygen exposure, or excessive damage.

This is why buyers who treat walnuts like a commodity often end up paying for it later in the plant: extra hand-sorting, more rework, inconsistent visuals, higher foreign material risk, and the toughest issue to manage—sensory complaints that appear weeks later. A practical defect and color specification helps you prevent those outcomes without over-buying.

- Defects directly affect: edible yield, labor, rework, scrap, and complaint risk.

- Color affects: customer acceptance, appearance consistency, and (in many programs) correlates with handling stress.

- Foreign material (FM) affects: food safety risk posture, line stops, and customer trust.

- Moisture and packaging affect: mold risk posture and oxidation drift during storage and transit.

Procurement reality: Two lots with the same “grade name” can behave differently. A buyer checklist helps you define the few parameters that actually prevent rework and complaints—without locking your program into unrealistic limits that reduce supply flexibility.

The hidden cost of vague walnut kernel specs

The cost of walnuts is easy to see on an invoice. The cost of weak specs is harder to see—but it shows up as: slower throughput, higher sorting labor, higher scrap, more quality holds, longer release times, and repeat issues that drain both QA and procurement teams.

A good industrial walnut kernel spec is not a “wishlist.” It is a tool to control outcomes: yield, line stability, complaint rate, and release speed.

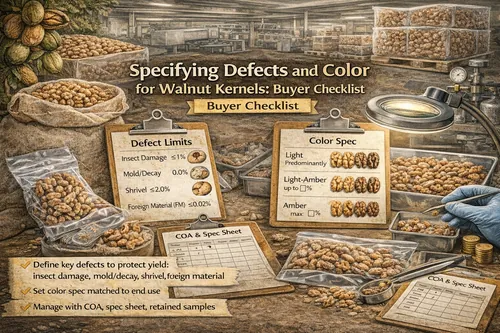

What to specify (minimum spec) to protect your walnut program

If you only specify “walnut kernels” and a general grade, you leave most of the risk in the gaps. The minimum industrial spec should define: format, defect posture, color acceptance, foreign material posture, moisture expectation, and packaging.

The minimum fields most industrial buyers should include

- Product & format: kernels / halves / pieces; raw vs. roasted; optional size range (pieces program).

- Color target: define acceptable range (example language provided below).

- Defect categories: define what matters (insect damage, mold/decay, shrivel, breakage, etc.).

- Foreign material posture: define shell fragment tolerance and escalation for high-risk FM.

- Moisture target: set a maximum or range and define how it will be verified.

- Packaging: lined cartons/bags, seal integrity expectations, lot code visibility, pallet config if relevant.

- COA requirements: which fields must appear and how lot IDs should match labels/documents.

- Receiving method: sampling plan and who makes the final acceptance decision.

Fast win: If you add only one thing to your walnut kernel purchasing language, add a clear definition of what you consider rejectable (especially mold/decay and high-risk foreign material) and how receiving will be performed. This single step prevents most “we thought it was acceptable” disputes.

Start with the use case: where specs should be tighter

Walnut kernels show up in products with very different tolerance for variability. Before you tighten anything, define what matters most in your finished product: appearance, flavor stability, texture, or foreign material risk. Then tighten only the parameters that drive those outcomes.

Typically higher sensitivity (tighten color and defect posture)

- Premium snack mixes (visible inclusions where color and uniformity drive acceptance)

- Confections (chocolate, clusters, bars—where color and bitter notes stand out)

- Bakery toppings (muffins, breads, pastries—where visual contrast is obvious)

- Dairy alternatives / mild bases (oxidation can show quickly against a mild flavor background)

- Long shelf-life SKUs or warm distribution lanes (higher oxidation drift risk)

Typically more tolerant (tighter where it matters, flexible where it doesn’t)

- Heavily flavored products (spiced, smoky, sweet coatings—cosmetic variability may be less visible)

- Fast-turn applications with short warehouse holds

- Milled/blended uses where kernels are not visible (buttery pastes, meals, inclusions in dense matrices)

A practical “spec tightness” framework

Think of your walnut kernel spec as two lanes:

- Premium lane: tighter color, tighter defect limits, often stronger sensory expectations and packaging protection.

- Standard industrial lane: broader color tolerance and realistic defect posture aligned to the finished product and price point.

Many buyers reduce costs without increasing complaints by running two lanes instead of forcing all applications into the strictest spec.

Terminology & formats: define what you are actually buying

A surprising amount of quality drift is not “bad walnuts”—it is mismatch between the buyer’s assumption and the supplier’s definition. The more clearly you define format and expectations, the fewer receiving disputes you’ll have.

Common industrial formats

- Kernels / halves: used in premium visible applications; breakage and appearance matter more.

- Pieces: used for inclusions and bakery; size distribution and foreign material posture often matter more than perfect halves.

- Meal / flour / milled walnut: color often less critical; oxidation posture and sensory stability remain important.

- Roasted: different sensory baseline and more processing exposure; define salt/oil/roast profile if applicable.

Why “pieces size” is not just a cosmetic detail

In pieces programs, size distribution affects: inclusion visibility, dosing accuracy, segregation in hoppers, and how well your line removes foreign material. If your process uses screens or sifters, a defined size range can reduce line variability.

Buyer tip: If you don’t need strict piece size, don’t over-spec it. But if your line has frequent segregation, bridging, or inconsistent dosing, size definition can be one of the cheapest fixes.

Defect limits: buy yield and reduce rework

Defect limits are not “extra paperwork.” They are a way to buy process stability. In walnuts, defect levels also connect to shelf-life behavior because damaged surfaces oxidize faster, and lots with higher stress history often drift more in storage.

Defect categories buyers commonly define

- Insect damage: rejectable kernels/pieces; reduces edible yield and can create bitter notes.

- Mold/decay: sensory and quality risk; many programs treat this as “no visible mold on receipt.”

- Shrivel / poor fill: impacts texture and visual appeal; may be more acceptable in milled/blended uses.

- Excess breakage: impacts sizing consistency (especially in halves programs).

- Off-odor / off-flavor: not always visible; requires sensory acceptance language.

- Foreign material (FM): shell fragments and other materials; often managed through both limits and controls.

Defects that matter most (and why)

1) Mold/decay: define the “stop the line” posture

Mold/decay is one of the most important defect categories to define because it triggers immediate concern during receiving. Even if actual microbiological risk is not confirmed by sight alone, visible mold is a high-impact quality signal that can create customer anxiety, internal escalation, and immediate hold decisions.

- Practical receiving language: “No visible mold/decay; any observation triggers QA hold and supplier notification.”

- Why it helps: removes subjective disputes and gives receiving a clear escalation rule.

2) Insect damage: buy edible yield (and reduce complaint risk)

Insect damage is a direct hit to edible yield and can create unpleasant sensory notes if present in meaningful quantity. The practical buyer approach is to specify an allowable maximum and define how receiving will evaluate it (by weight percent or count).

- Where it matters most: premium snacks, confections, mild-flavor bases.

- Where you may relax: heavily flavored, milled, or fast-turn uses (within reason).

3) Shrivel/poor fill: define texture expectations

Shrivel affects texture, mouthfeel, and visual perception. Some products tolerate it; others don’t. In a premium inclusion, shrivel looks “old.” In a blended base, it may be irrelevant.

- Where it matters most: visible inclusions, premium bakery toppings.

- Buyer-friendly spec language: “Minimal shrivel/poor fill; rejectable if texture is noticeably woody or dry.”

4) Excess breakage: match format to your process

For halves programs, excess breakage is a value issue and often a visual issue. For pieces programs, breakage might be normal—what matters is size distribution and dust/fines.

- Halves programs: define maximum pieces and broken kernels allowed.

- Pieces programs: define size range and limit dust/fines if it causes dosing or housekeeping issues.

5) Off-odor/off-flavor: make sensory part of acceptance

Many of the complaints buyers fear—painty, rancid, musty, stale—are sensory first. If your spec doesn’t give your team permission to reject on sensory, you may be forced to accept borderline lots that create issues later.

- Practical language: “Clean, fresh walnut aroma; no rancid/painty/musty odor. Sensory non-conformance is rejectable.”

- Best practice: keep a retained “golden lot” reference sample for training and consistency.

How to set defect limits practically (without over-buying)

- Start with what causes the most plant pain: rework, sorting, line stops, complaints.

- Align limits to format (halves vs pieces) and application sensitivity.

- Decide if you need a premium lane and a standard industrial lane.

- Define rejectable conditions clearly (especially visible mold and high-risk foreign material).

- Specify how acceptance will be measured (sample size, method, and decision authority).

Useful framing: Defect limits are a way to buy process stability. Lower defects usually mean less rework, fewer line interruptions, and fewer customer complaints—especially for premium visible uses and long shelf-life programs.

Foreign material (FM): specify limits, but also specify controls

Foreign material is the category where industrial buyers often need two things at the same time: a limit and a control story. Limits alone do not prevent issues; controls are what reduce occurrence. The spec should define what is acceptable, what is rejectable, and what triggers escalation.

Common FM types in walnut kernels

- Shell fragments: the most common walnut-related FM; may be tolerable at low levels depending on application and customer posture.

- Hard foreign material: stones, glass, hard plastic—high risk; typically “zero tolerance” or immediate escalation.

- Metal: controlled through magnets and metal detection; define escalation if found in receiving.

- Soft foreign material: plastic film, string, paper; still a complaint risk and can be hazardous if large.

How to write FM language that actually works

- Define categories by risk: shell fragments vs. hard FM vs. metal vs. soft FM.

- Include an escalation rule: “Any hard FM triggers immediate hold + supplier notification + documented investigation.”

- Pair with controls: ask the supplier what screening, aspiration, optical sorting (if used), and metal controls are in place.

- Match your line capability: if your process cannot remove shell fragments effectively, tighten shell fragment tolerance.

Practical buyer mindset: FM limits protect your customer relationship. FM controls protect your operation. You want both in the conversation—especially for high-volume industrial walnut programs.

Color: define what “acceptable” means for your product

Color is both a commercial expectation and (sometimes) a signal of handling history. Lighter, more uniform walnut kernels are often preferred for premium visible applications. Broader ranges may be perfectly acceptable in robust or blended uses—if you define that clearly and document it.

Common ways the industry talks about walnut color

Walnut programs often use color categories (names may vary by supplier program) and/or percentage language such as “mostly light” or “maximum dark.” The key is to translate the idea into a receiving-friendly rule: what is allowed and what triggers rejection.

When to specify color tightly

- Premium snacks and inclusions where walnuts are visible

- Confections and bakery toppings where appearance drives acceptance

- Customer programs that reject variability (tight brand standards)

- Products where dark kernels are interpreted as “old” by consumers

When you may relax color requirements (without changing outcomes)

- Milled or blended applications (butters, pastes, flours)

- Heavily flavored products

- Fast-turn programs where cosmetic variability does not affect outcomes

How to define color without over-buying

- Use clear language: “predominantly light” vs. “light/amber acceptable” vs. “maximum dark kernels X%.”

- Use reference photos: if your QA team uses a “golden lot,” document it and train receiving against it.

- Define the evaluation method: percentage by count in a standard sample is often more repeatable than informal impressions.

- Match color to value: don’t pay premium color pricing for applications where color is not visible or not important.

Color and shelf-life: what buyers should know

Color alone does not “cause” rancidity, but lots that experienced more handling stress (mechanical damage, high heat exposure, poor storage) may show greater variability and may drift faster. This is why many industrial buyers treat color as both a commercial field and a quality signal—especially when combined with sensory checks and defect posture.

Sampling & receiving method: make acceptance repeatable

Even the best walnut kernel spec fails if receiving is inconsistent. A practical receiving method makes acceptance repeatable and reduces disputes. The goal is not to create a laboratory; it’s to create a consistent decision that aligns with your risk tolerance and your customer expectations.

Recommended approach (buyer-friendly and scalable)

- Sample representatively: take increments across multiple cases/bags (not just the top of one case).

- Create a composite sample: mix increments into one composite for inspection.

- Standardize sample size: choose a consistent weight (example: 500g–1000g) so results are comparable lot to lot.

- Perform three checks: packaging/label + sensory odor + visual for color/defects/FM.

- Record results: simple checklists build a defensible history (especially when a complaint arises later).

- Retain a labeled sample: keep a retain by lot for investigation and shelf-life tracking.

How to avoid “subjective” color disputes

- Evaluate under consistent lighting (avoid mixed lighting and shadows).

- Use a reference image (or retained “golden lot” sample) for your target.

- Define what “too dark” means (e.g., “no more than X% dark kernels in the inspection sample”).

Repeatability beats perfection: A consistent 10-minute receiving method prevents more production pain than an inconsistent 60-minute inspection that changes depending on who is working that day.

Moisture note: why it still belongs in a walnut kernel spec

This article focuses on defects and color, but in walnuts moisture is tightly linked to mold risk posture and shelf-life stability. Even if you don’t request extensive testing, set a moisture expectation and define how it will be verified (COA and/or receiving checks).

How buyers typically use moisture in decision-making

- As a release gate: moisture must be within spec for acceptance.

- As a storage decision input: borderline moisture lots may require faster turns or cooler storage.

- As a risk signal: if moisture is consistently high across multiple lots, investigate storage and transit lanes.

Packaging notes that protect quality and reduce oxidation drift

Packaging is part of the spec because it affects oxygen exposure, moisture events, and how quickly lots drift during storage and transit. A strong packaging spec reduces variability and helps your plant maintain consistent quality after opening.

Common industrial packaging formats for walnut kernels

- Lined cartons/bags: common for kernels and pieces; define liner type and seal expectations when relevant.

- Multiwall bags with liners: common for pieces; define bag integrity and labeling clarity.

- Barrier packaging (program-dependent): used for oxidation-sensitive programs; higher protection but typically higher cost.

- Pack size options: match pack size to consumption rate to reduce repeated opening and oxygen exposure.

Packaging details that prevent the most pain

- Seal integrity expectations: reduces oxygen and moisture events in transit and storage.

- Pack size alignment: helps slow-use lines avoid partial open containers sitting for days.

- Lot code visibility: supports traceability, rotation, and faster issue isolation.

- Pallet stability: reduces crushed cases, torn liners, and exposure.

Simple rule: If you’ve ever had rancidity complaints increase after opening, packaging format and post-open handling are part of the solution—not just raw material quality.

Storage & logistics: protect walnuts from heat, oxygen, and time

Even high-quality walnut kernels can drift if storage and transit conditions are poor. Industrial buyers who reduce complaint rates usually focus on a few controllable factors: temperature, time, oxygen exposure after opening, and inventory rotation discipline.

Practical storage best practices for bulk walnut programs

- Keep cool and consistent: avoid warm storage and temperature cycling when possible.

- Protect from light: light exposure can accelerate sensory drift in oils over time; keep packaging closed and stored appropriately.

- Control oxygen exposure after opening: reseal liners, use clips/ties, and minimize headspace.

- Rotate inventory with discipline: use FIFO/FEFO logic aligned to your internal shelf-life policy.

- Prevent moisture events: avoid wet floors, damaged pallets, and high-humidity staging when possible.

Transit lane considerations (especially for export or long domestic lanes)

- Heat exposure: hot lanes can accelerate oxidation drift; consider seasonality in planning.

- Dwell time: delays at ports or cross-docks can create unexpected heat/time exposure.

- Container handling: protect packaging from punctures and crushing.

COA checklist: fields that support acceptance and traceability

COA content varies by supplier and destination requirements. A practical COA supports receiving decisions and traceability, and it shortens the time your product sits on quality hold.

Common COA fields buyers request

- Lot identification: must match packaging labels and shipping documents.

- Product description: kernels/halves/pieces; raw/roasted; any size or style identifiers.

- Moisture: value and (if provided) method reference.

- Allergen statement: tree nut (walnut) declaration aligned to labeling needs.

- Country of origin: for compliance and labeling workflows.

- Traceability identifiers: production/shipment identifiers for issue isolation.

- Defect summary (if provided): key defect categories aligned to your spec.

- Microbiology (program-dependent): aligned to your category requirements.

Documentation you may need depending on customer/program

Some buyers require additional documentation beyond the COA. If you anticipate customer audits or strict program requirements, ask early: documentation availability varies by product and supplier program.

- Food safety certifications and audit status (program-dependent)

- Allergen control statements and facility allergen profile

- Recall/traceability program summaries

- Destination-specific compliance documents for export programs

If your customers require additional documents (audit certificates, recall program summaries, food safety plan elements), request availability early. Documentation availability varies by program and destination.

Walnut kernel spec template (copy/paste) for industrial buyers

Below is a buyer-friendly spec template you can adapt. It is intentionally written in practical language so it works in procurement conversations and supports repeatable receiving decisions. Use it as a starting point and tighten only the fields that drive your finished product outcomes.

How to use this template: Pick your lane (premium vs standard). Then define: format, color acceptance, defect posture, foreign material posture, moisture expectation, packaging, and COA fields. If a field doesn’t matter to your use case, keep it flexible.

Template

PRODUCT: Walnut kernels (specify: halves / pieces / kernels) | Raw (or Roasted: define roast profile if applicable)

INTENDED USE: (snack mix / bakery topping / confection inclusion / blended base / milled)

LANE: (Premium / Standard Industrial)

COLOR EXPECTATION (define acceptance):

- Target: (e.g., predominantly light / light+amber acceptable / max dark kernels __% in inspection sample)

- Receiving method: visual check under consistent lighting; compare to reference photo or retained “golden lot”

- Rejectable: (define what triggers rejection or QA hold)

DEFECT POSTURE (define key categories you care about):

- Mold/decay: no visible mold/decay; any observation triggers QA hold and supplier notification

- Insect damage: max __% (by weight or count) in inspection sample

- Shrivel/poor fill: max __% (if relevant to your application)

- Excess breakage / fines: define max pieces/broken (halves programs) or max fines/dust (pieces programs)

- Sensory: clean, fresh walnut aroma; no rancid/painty/musty/stale notes (rejectable)

FOREIGN MATERIAL (FM):

- Shell fragments: max __ (define tolerance aligned to your line capability)

- Hard foreign material: rejectable / immediate hold and escalation

- Metal: rejectable / immediate hold and escalation

- Controls (supplier to confirm): screening/aspiration, optical sorting (if used), magnets/metal detection

MOISTURE:

- Target: max __% (or range __–__%)

- Verification: COA required; receiving verification (as needed / program-dependent)

PACKAGING:

- Format: lined cartons or bags; define pack size and pallet configuration if needed

- Seal integrity: liners sealed; no punctures or water damage

- Labeling: product description + lot code visible; country of origin if required

COA REQUIREMENTS (minimum):

- Lot ID matching packaging labels + shipping documents

- Moisture

- Allergen statement (walnut)

- Country of origin

- Traceability identifiers (production/shipment)

- Additional testing (program-dependent): defect summary, microbiology, etc.

RECEIVING / ACCEPTANCE:

- Sampling: composite sample from multiple cases/bags per lot

- Decision authority: QA release required (if applicable)

- Retains: retain labeled sample per lot for shelf-life and investigation

CLAIMS / NON-CONFORMANCE (optional but recommended):

- Notification within __ days of receipt

- Provide photos, sample, and receiving results

- Agree on corrective action / replacement / credit process

Receiving inspection checklist (buyer-friendly)

A good receiving checklist is short, repeatable, and aligned to your spec. The goal is to catch issues early, document them clearly, and prevent borderline lots from entering production.

- Packaging integrity: no punctures, water damage, broken seals; correct labeling and lot codes.

- Documentation match: COA lot ID matches case labels and shipping documents.

- Odor check: clean, fresh walnut aroma; no painty, rancid, musty, or stale notes.

- Visual check: color consistency aligned to your spec; minimal shell fragments/debris; no visible mold.

- Foreign material posture: confirm FM aligns with your tolerance; escalate immediately on high-risk FM.

- Moisture verification: confirm against target (especially in warm or humid seasons).

- Retains: keep a retained sample by lot for complaint investigation and shelf-life tracking.

QA tip: For flavor-sensitive programs, define a sensory acceptance standard and keep a “golden lot” reference sample. This turns “I think it smells off” into a consistent and defensible decision.

What to do when something looks borderline

Many receiving problems are not obvious “rejects”—they’re borderline lots that create issues later. A practical approach:

- Hold first, decide second: if sensory is questionable or mold is suspected, place the lot on QA hold immediately.

- Document: photos, notes, sample weight, and what you observed (odor terms, defect types).

- Escalate with a structured message: lot ID, PO, receiving date, findings, and requested action.

- Protect your production plan: keep an alternate approved lot or lane for continuity.

Questions to ask suppliers (procurement-focused)

The best supplier conversations are the ones that map directly to outcomes: defect posture, color consistency, foreign material control, and shelf-life stability. Use the questions below to qualify suppliers and to align programs before you scale volume.

Questions that map directly to defect and color outcomes

- What are typical defect ranges for this grade and crop year? Helps set realistic limits and buffers.

- How is color classified and controlled? Ask how lots are graded, what drives variability, and whether a reference system is used.

- What sorting and foreign material controls are used? Screening, aspiration, optical sorting (if used), metal controls.

- What is your approach to mold/decay prevention? Storage posture, handling controls, and escalation when an issue is observed.

- What are storage and shipping practices? Connect to oxidation risk and transit lane exposure.

- How do you manage lot traceability? What identifiers appear on packaging and COA; how quickly can you isolate a lot?

- What documentation is available? COA, allergen, COO, traceability, and compliance docs as needed.

Questions that prevent “surprises” after you scale volume

- What is the plan for consistency across multiple shipments? Single source lots vs blended; how they maintain spec conformance.

- What is your standard for sensory acceptance? How do they evaluate rancidity risk and off-odors?

- How are non-conformances handled? Credit/replacement process, timelines, and required documentation.

- Can you support two lanes? Premium lane for visible applications and standard lane for blended/milled uses.

When to tighten specs (and when not to)

Tight specs protect quality but can reduce supply flexibility and increase costs. Tighten specs when your product is appearance- or flavor-sensitive, your shelf-life target is long, your lane is warm/long, or your customers have strict expectations. If your application is robust and inventory turns are fast, broader ranges may be acceptable without changing outcomes.

Best practice: Align your spec to your finished product, not to a “perfect walnut.” Over-specification is one of the most common reasons industrial buyers pay more than necessary.

FAQ: walnut kernel defects and color specs

Do defects always show up at receiving?

Not always. Some issues show up later as faster oxidation drift or higher sorting burden during production. That’s why retained samples, documented receiving results, and defined sensory checks are useful—especially in sensitive programs.

Is darker color always a “fail”?

No. It depends on your product and your customer expectation. Darker kernels may be acceptable in robust or blended applications, but premium visible products often require lighter, more uniform appearance. Define “acceptable” in your spec to reduce subjective disputes.

What is the best way to specify foreign material for walnuts?

Separate FM into categories by risk: shell fragments (often manageable), hard foreign material (high risk), and metal (high risk). Define escalation rules for high-risk FM and ask the supplier to confirm their preventive controls (screening, aspiration, optical sorting if used, and metal detection).

How do I reduce rancidity complaints over time?

Start with low-defect lots, then protect them: cool storage, minimize oxygen exposure after opening, avoid heat during transit, and align packaging size with consumption rate so product doesn’t sit open in partial containers.

Do I need microbiology tests for walnut kernels?

It depends on your finished-product category and customer requirements. Some programs require microbiology documentation, while others focus on preventive controls and supplier qualification. Align requests to your risk posture, destination requirements, and customer expectations.

How do I avoid over-buying by specifying color too tightly?

Start from the finished product need. If walnuts are visible and customers care, specify tighter color. If walnuts are blended or milled, broaden color tolerance and specify what matters more (sensory, oxidation posture, and foreign material control). Use reference photos or a “golden lot” sample so receiving decisions are consistent.

Next step

If you share your application (snacks/bakery/confectionery/etc.), format (halves/pieces), destination, and target shelf life, we can recommend practical defect and color checkpoints (and moisture fields) and packaging options that match your program. Use Request a Quote or email info@almondsandwalnuts.com.

For sourcing, visit bulk walnut products or browse the full products catalog.