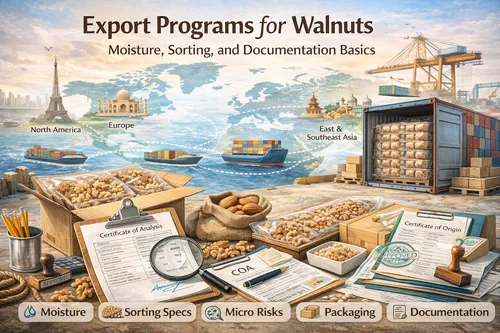

Export Programs for Walnuts: Moisture, Sorting, and Documentation Basics

Export walnut programs succeed or fail on three basics: moisture control (to protect quality in transit), sorting/spec clarity (so buyers receive the grade they expect), and documentation readiness (so shipments clear smoothly). This guide summarizes the checkpoints that reduce rejections, delays, and costly rework.

Previous: In-Shell Walnuts (Natural vs Bleached): Market Preferences and Handling Notes • Next: Specifying Defects and Color for Walnut Kernels: Buyer Checklist

Related: bulk walnut products • products catalog • request a quote

Why export programs need tighter controls

Export adds exposure time and variability: longer transit, temperature swings, port dwell, and more handling steps. That means small differences in moisture, packaging integrity, and grade definition can show up as big differences at destination.

- Moisture + humidity can drive clumping, mold risk, or quality drift during long voyages.

- Oxidation risk rises with heat exposure and oxygen ingress (especially for kernels and pieces).

- Sorting clarity matters more because return logistics are expensive and slow.

Export-ready formats (choose the right risk profile)

Start with the end-use and the risk tolerance of the destination lane. Export programs typically ship as:

- In-shell: often more robust physically; still needs moisture control and clean handling.

- Kernels (halves/pieces): higher oxidation sensitivity; benefits from strong oxygen barriers.

- Diced/pieces/meal: highest surface area; greatest need for packaging and shelf-life alignment.

Buyer shortcut: For long transit lanes, treat packaging + oxygen exposure as “spec items,” not just logistics details.

Moisture basics that prevent export problems

Moisture targets are the simplest way to reduce two major export risks: micro growth and quality drift. Even if the product leaves the warehouse “fine,” container conditions can amplify moisture-related issues.

- Confirm target + max moisture on the spec sheet and COA (don’t rely on “typical”).

- Align packaging with moisture risk: liners, seals, and barrier films matter more on ocean freight.

- Plan for destination climate: humid ports and warm warehouses can stress marginal product.

- Define receiving SOP: how quickly product is moved into proper storage after unloading.

Sorting, grade, and color: define it so both sides match

Export rejections often come from expectation gaps rather than “bad” walnuts. Make sorting language and acceptance criteria explicit:

- Style/size: halves, pieces, diced size range; include sieve/size definitions when relevant.

- Color expectations: agree on acceptable range and the method used (if applicable).

- Defect limits: insect damage, shrivel, dark pieces, embedded shell, foreign material.

- Lot consistency: confirm whether lots are single-lot or blended to spec.

Processing and shelf-life considerations for export lanes

Walnuts are oxidation-sensitive, and export lanes add time. Match your shelf-life target to the lane reality: production → export staging → ocean/air transit → customs → destination warehousing → manufacturing use.

- Heat exposure accelerates rancidity risk; ask about storage conditions before loading.

- Oxygen management (barrier packaging, sealed liners) matters most for kernels and pieces.

- Define remaining shelf-life at arrival (minimum months remaining) if your program needs it.

Packaging options for bulk export programs

Export packaging aims to protect against moisture pickup, oxygen ingress, and handling damage. Common bulk setups include:

- Lined cartons/bags for kernels/pieces; specify liner type and seal method.

- Sealed bulk bags for meal/flour; ensure dust and clumping controls match your plant.

- Container loading plan: pallet pattern, dunnage, and label visibility for destination inspections.

Share receiving constraints (forklift access, pallet heights, storage temperature/humidity) early to avoid “export-ready” product arriving in a non-export-ready configuration.

Documentation basics buyers typically request

Documentation needs vary by destination and customer category, but export programs typically move faster when the supplier can provide a standard packet on request:

- COA (with the exact spec fields your QA will release against).

- Allergen statement (tree nut), plus any cross-contact declarations relevant to your program.

- Country of origin (COO) and traceability/lot identifiers.

- Micro documentation as required by the buyer category (varies by application).

- Export paperwork support when needed (program dependent): invoices/packing lists and other supporting compliance documents.

Practical tip: Ask your supplier to send a sample document set before the first shipment. It reveals gaps early—before a container is already booked.

How to request a quote with fewer back-and-forths

For export walnut programs, include these details up front:

- Destination country/port, Incoterms preference, and target ship window.

- Format (in-shell vs kernels; halves/pieces/diced/meal) and grade/color expectations.

- Moisture target/max, defect limits, foreign material limits, and micro requirements.

- Packaging (liner type, carton/bag spec, pallet configuration) and container loading constraints.

- Volumes (first order + annual forecast) and any minimum remaining shelf-life at arrival.

- Documentation packet needed for your importer/customer (COA fields, allergen, COO, etc.).

Next step

If you share your destination lane (country/port), format (in-shell vs kernels), and your must-have spec fields (moisture + defects/color + micro), we can recommend an export-ready packaging lane and a quote checklist that reduces customs delays and receiving rejections. Use Request a Quote or email info@almondsandwalnuts.com.