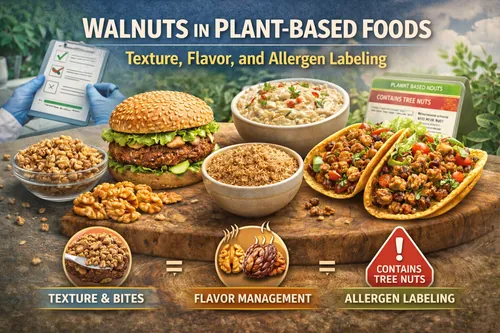

Walnuts in Plant-Based Foods: Texture, Flavor, and Allergen Labeling

Industrial guide for walnuts in plant-based foods: how walnut format impacts texture and bite, how to manage flavor and oxidation, and what buyers should align on for allergen labeling and documentation. Includes a practical spec checklist, processing notes, and bulk packaging options.

Previous: Walnut Pieces for Dairy Fruit Prep and Toppings: Migration and Softening Control • Next: Allergen Controls for Bulk Walnut Programs: Receiving, Storage, and Labeling

Related: bulk walnut products • products catalog • request a quote

Where walnuts fit in plant-based product design

Walnuts can play multiple roles in plant-based foods—sometimes as a visible inclusion, sometimes as a functional base. The best format is the one that hits your texture and flavor targets with minimal processing and a stable supply lane.

- Plant-based “meat” style products: adds bite, fat perception, and a more complex chew when used as pieces or coarse meal.

- Dips/spreads and cultured-style bases: walnut meal or paste supports body, mouthfeel, and smooth texture.

- Ready meals / fillings: pieces can provide contrast; tighter defect controls reduce visible variation.

- Sauces and dressings: finer formats can improve emulsion stability and reduce oil separation.

Practical note: plant-based products often have less “forgiveness” on flavor drift. If your finished product has a long shelf-life target, tighten oxidation controls and packaging early.

Format selection for texture and processing

Walnut halves/pieces

Best for visible inclusions and “artisan” texture. Confirm cut/size expectations and acceptable breakage. Larger pieces can soften in high-moisture systems over time, so match inclusion size to water activity and hold time.

Walnut meal / milled walnut

Useful for uniform dispersion and texture control. Buyers should confirm particle size distribution (PSD) and flow behavior because PSD drives mouthfeel (grit vs smoothness), hydration speed, and processing consistency.

Walnut paste / walnut butter

Often selected when you need a smooth base, faster batching, and tighter texture consistency. Validate separation tendency (oil rise), oxidation posture, and packaging/handling requirements (pails/drums/totes).

Raw vs roasted formats

Roasted walnuts can boost aroma and reduce “green” notes, but they often increase oxidation sensitivity and require tighter control on roast profile. Align roast preference to your flavor target, shelf-life, and any downstream heat step.

Flavor management: what buyers should watch

In plant-based applications, walnuts can contribute desirable nutty complexity—but they can also amplify bitterness or rancid notes if oxidation is not controlled. Common flavor drivers include roast intensity, lot-to-lot variability, and storage conditions.

- Bitterness: can be more noticeable in low-salt or lightly seasoned plant-based SKUs; confirm sensory expectations up front.

- Roast profile: specify light/medium/dark (or temperature/time window) if you buy roasted walnuts to reduce variability.

- Oxidation/rancidity risk: increases with heat, oxygen, and light exposure—especially for milled/paste formats.

- Pairing strategy: in savory bases, walnuts often perform well with umami, smoke, pepper, herbs, and mild acids (but acids can highlight bitterness in some systems).

Allergen labeling and controls: what to align on early

Walnuts are a tree nut allergen, so plant-based brands typically need strong labeling and cross-contact controls. From a buying standpoint, the goal is to avoid surprises during label review and audits.

- Allergen statement: request a current allergen statement for the walnut ingredient and confirm how it should be declared in your market.

- Cross-contact posture: ask what other allergens are handled in the supplier program and what segregation/cleaning controls are in place.

- Traceability: confirm lot coding, COA linkage, and documentation availability for audits and complaint investigations.

- Label consistency: if you use multiple walnut formats (pieces + paste), align naming conventions to reduce artwork churn.

Spec checkpoints buyers should confirm

Typical checkpoints include moisture, size/cut specification, defect and color limits, roast profile (if applicable), and microbiological requirements aligned to your product category. For plant-based foods, a few items often matter more:

- Moisture target: supports stability and reduces mold/storage risk.

- Defect/color limits: important for light-colored bases where dark pieces are visually obvious.

- Micro requirements: align to refrigerated vs shelf-stable processing and whether your process includes a kill step.

- PSD / mesh distribution (milled): key driver of smoothness, hydration, and batch repeatability.

- Oxidation posture: define how “fresh” needs to be for your shelf-life target and hold time.

Processing and shelf-life considerations

Walnuts are oxidation sensitive. Packaging, oxygen exposure, heat, and light can all reduce shelf life. Roasted formats and milled/paste formats generally need tighter handling controls than whole kernels. Match your ingredient storage plan to your finished-product shelf-life target and distribution conditions.

Packaging options for bulk programs

Bulk programs commonly use lined bags/cartons for pieces and meal, and pails/drums/totes for paste/butter and oils. For plant-based manufacturers, the most common failure mode is “good ingredient, wrong packaging for the hold time.”

- Pieces / meal: lined cartons or bags; consider higher-barrier liners when lead times or storage windows are long.

- Paste / butter: pails, drums, or totes; confirm resealability if partial-use is expected and clarify storage temperature expectations.

Share receiving constraints (pallet pattern, dock schedule, temperature limits) and any repack requirements early to avoid delays.

How to request a quote with fewer back-and-forths

Send: product + format (pieces/meal/paste), target specs (moisture, defects/color, PSD if milled, micro requirements), raw vs roasted preference (and roast profile if applicable), packaging, first order volume, annual forecast, destination, and timeline. If you have a spec sheet, include it—this is the fastest path to an accurate offer.

Next step

If you share your plant-based application, target texture (smooth vs chunky), flavor target (raw vs roasted), labeling market (where you sell), packaging preference, and destination, we can confirm common spec targets and the fastest supply lane. Use Request a Quote or email info@almondsandwalnuts.com.