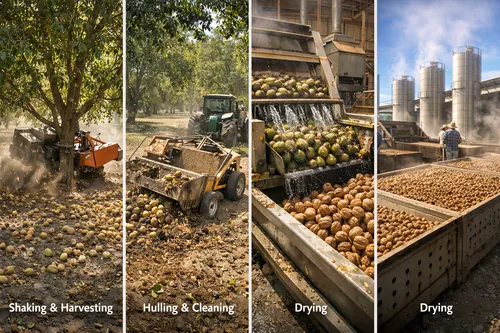

Walnut Harvest Process: Shaking, Hulling, and Drying Flow

California walnut harvest guide for buyers: what happens during shaking, pickup, hulling/cleaning, and drying— and how those steps influence kernel color, defect rates, moisture stability, food-safety risk, and finished shelf life in bulk walnut programs.

Previous: Pests and Diseases in California Walnuts: Quality and Food Safety Notes • Next: Drying Walnuts Safely: Moisture Targets, Mold Risk, and Storage

Related: bulk walnut products • products catalog • request a quote

Why harvest flow details matter to buyers

Walnuts are unusually sensitive to time, moisture, and temperature during harvest. The same orchard can deliver very different results depending on how quickly nuts move from the ground to hulling and then to drying. For procurement and QA teams, harvest practices show up as:

- Color outcomes: darker kernels and higher “amber” incidence when harvest timing or handling is stressed.

- Defects: increased mold risk, staining, insect damage visibility, shell/husk residue, or shrivel.

- Shelf-life performance: higher oxidation/rancidity risk if moisture is not stabilized quickly.

- Foreign material (FM): more field debris if pickup/cleaning is not tight.

Buyer shortcut: when a supplier can clearly describe their harvest-to-dry timeline and controls, you typically see fewer surprises on incoming inspection and finished-product shelf life.

High-level harvest flow (field to dryer)

At a practical level, the harvest process is a sequence designed to remove the green husk, reduce moisture safely, and protect kernel quality before long-term storage:

Shaking → Ground pickup / windrow → Transport to huller → Hulling / cleaning → Drying → Inbound to storage / warehouse

Step 1: Shaking and timing decisions

Harvest begins when maturity and market objectives align. “When” matters because over- or under-mature nuts can shift color and defect rates. Shaking dislodges walnuts; what happens next is where quality can be won or lost.

What can go wrong

- Harvest too early: higher moisture and increased drying load; potential quality variability.

- Harvest too late: increased exposure to rain/dew cycles, staining, and mold pressure in some conditions.

- Extended time on the ground: moisture uptake and contamination risk rise, especially in humid or wet weather.

What buyers can ask

- Typical harvest window and how weather shifts the plan.

- Target maximum time between ground pickup and hulling/drying.

- How lots are segregated by orchard/block or day of harvest.

Step 2: Pickup, field cleaning, and transport

After shaking, walnuts are typically swept/windrowed and picked up mechanically. This step influences foreign material and the amount of field moisture/debris carried into hulling.

What affects quality here

- Soil and debris load: more sticks, leaves, stones = higher FM burden downstream.

- Handling damage: rough handling can increase shell damage, which can raise defect risk later.

- Staging conditions: warm staging + high moisture = higher mold/quality risk.

Procurement angle: FM control is not only a plant issue—field pickup discipline can materially reduce FM risk and sort losses later in the process.

Step 3: Hulling and cleaning

“Hulling” removes the green husk (outer layer) and typically includes initial cleaning steps. The objective is to remove husk material and reduce contamination before the dryer.

Why hulling speed matters

- Staining control: prolonged contact with wet husk material can contribute to darkening or staining.

- Mold risk control: wet organic residue increases microbial risk if nuts sit before drying.

- Consistency: cleaner, more uniform product dries more predictably.

Buyer checkpoints

- Cleaning steps used before drying (screens, air separation, etc.).

- How lots are identified and traced through hulling.

- Foreign material posture and metal detection approach (where applicable later in the chain).

Step 4: Drying flow (stabilizing moisture safely)

Drying is the critical stabilization step. The goal is to reduce moisture to a safe range for storage without over-drying (which can increase breakage) or under-drying (which increases mold and quality risk).

What buyers should understand

- Drying is both a quality and food-safety control: it reduces the conditions that support mold growth.

- Uneven drying = uneven risk: pockets of higher-moisture nuts can drive lot quality issues later.

- Heat management matters: excessive heat can contribute to flavor drift and quality loss.

If your program is sensitive to shelf life, it’s reasonable to ask how moisture is verified and how the supplier prevents re-wetting during cooling, staging, and loading.

Quality checkpoints that connect directly to procurement specs

Harvest and drying decisions connect to measurable specs that show up on COAs and receiving inspections. For kernel programs, buyers commonly align around:

- Moisture: incoming moisture target and allowable tolerance.

- Color / grade expectations: especially when “light” color or premium grade is required.

- Defect thresholds: insect damage, mold/decay, foreign material, shell fragments.

- Sensory: clean, fresh aroma; no rancid or musty notes.

- Documentation: COA, microbiology (as applicable), allergen statement, country of origin, lot traceability.

Tip: if you see unexpected color drift or higher defect rates, ask about the harvest-to-hull timeline, rain events during harvest, and how lots were segregated (by block/day).

How buyers use harvest knowledge in sourcing decisions

The goal isn’t to become an agronomist—it’s to reduce procurement risk. A practical approach is:

- Qualify supply lanes early for SKUs that demand light color or long shelf life.

- Request a harvest/handling summary (especially for premium grades or sensitive applications).

- Align receiving and storage posture with what the harvest flow delivers (temperature control, turnover cadence).

- Plan crop-year timing around your launch and forecast so you’re not forced into aged inventory.

Next step

If you tell us the format you buy (in-shell vs kernels vs pieces/meal), your shelf-life target, and where the product ships, we can recommend the most practical harvest-and-dry documentation questions to ask—and which specs matter most for your risk posture. Use Request a Quote or email info@almondsandwalnuts.com.