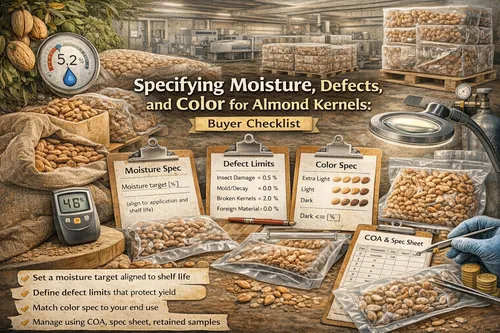

Specifying Moisture, Defects, and Color for Almond Kernels: Buyer Checklist

Industrial buyer checklist for almond kernels: how to specify moisture targets, defect limits, and color expectations to protect yield, line performance, and shelf-life stability. Includes spec and COA fields, receiving inspection checklist, packaging notes, and supplier questions for bulk almond programs.

Previous: Allergen Controls for Bulk Almond Programs: Receiving, Storage, and Labeling • Next: Oxidation and Rancidity Control in Almond Ingredients: Storage and Packaging

Related: bulk almond products • products catalog • request a quote

Why moisture, defects, and color specs matter in bulk almond programs

In industrial buying, a spec is not just a quality document—it is a tool to buy predictable production outcomes. The three fields that most directly reduce surprises are:

- Moisture: stability and storage behavior.

- Defects: edible yield, rework, and complaint risk.

- Color: appearance consistency and customer expectations.

Procurement reality: Two lots that meet the same “grade” label can run differently on your line. A buyer-facing checklist helps you define the few parameters that protect your finished product.

Start with the use case: how sensitive is your product?

Before tightening specs, define what “failure” looks like in your application. Different products tolerate different levels of variability.

Typically higher sensitivity

- Premium snack mixes and inclusions where almond appearance is visible

- Confections (color and uniformity expectations)

- Dairy alternatives and mild bases (flavor drift shows quickly)

- Long shelf-life SKUs or warm distribution lanes

Typically more tolerant

- Heavily flavored or spiced products

- High-turn bakery where inventory holds are short

- Applications where almonds are milled/blended and appearance is not visible

Moisture: the stability field buyers should not ignore

Moisture is one of the most useful “early warning” fields because it connects to storage behavior and shelf-life stability. In practice, moisture is also the field that can drift if handling or storage is weak.

What to define in your spec

- Moisture limit/target: align to your shelf-life needs, climate, and holding time.

- Test method reference (if applicable): helps reduce disputes if results differ.

- Receiving verification plan: decide if you will spot-check, test every lot, or test only in warm seasons.

When to tighten moisture expectations

- Long holding periods

- Warm storage or transit lanes

- Flavor-sensitive products

- Programs where mold-risk posture or customer audits are strict

Defects: buy yield and line stability (not just “quality”)

Defects increase rework, reduce edible yield, and create line and complaint risk. Your goal is to specify the defect categories that create the biggest pain in your operation.

Defect categories buyers commonly track

- Insect damage: rejectable kernels and reduced yield.

- Mold/decay: sensory and food-safety posture concern; typically treated as “zero tolerance” visually at receiving.

- Foreign material (FM): shell fragments, stones, metal/plastic risk managed through sorting and controls.

- Shrivel/poor fill: texture and appearance issues; may affect processing performance.

- Broken kernels: impacts sizing and consistency depending on your format requirements.

How to set defect limits practically

- Define the few defects that cause the most rework in your plant.

- Align limits to the format (whole kernels vs pieces; blanched vs natural).

- Decide whether you need tight “premium” limits or a more flexible “standard industrial” lane.

Useful framing: Defect limits are a way to buy process stability. Fewer defects usually mean fewer line stops, fewer customer complaints, and more predictable finished-product performance.

Color: when to specify and how to avoid over-buying

Color matters most when almonds are visible to the consumer or when your customers equate lighter, more uniform kernels with quality. The risk is over-buying: overly tight color specs can reduce supply flexibility and increase costs without improving outcomes in robust applications.

When to specify color tightly

- Premium snacks and inclusions

- Confections and bakery toppings where appearance is front-and-center

- Customer programs that reject visible variability

When you may relax color requirements

- Milled or blended applications (butters, pastes, flours)

- Heavily flavored products where visual differences are minor

- Fast-turn programs where cosmetic variation does not affect acceptance

How to define “acceptable” color

- Use clear language: “uniform, light appearance” vs “no dark/brown kernels” depending on your needs.

- If your team uses reference photos or a “golden lot,” document it as part of your receiving standard.

Packaging notes that affect moisture and quality stability

Packaging is part of the spec because it protects moisture and reduces quality drift during storage and transit.

Common packaging elements for bulk almond kernels

- Lined cartons or bags: common for kernels and cuts.

- Seal integrity expectations: reduce moisture events and contamination risk.

- Lot code visibility: supports traceability and rotation.

- Pack size alignment: reduces repeated opening and exposure for slow-use lines.

COA checklist: fields that support acceptance and traceability

COA content varies by supplier program and destination requirements. A practical COA supports receiving decisions and traceability.

Common COA fields buyers request

- Lot identification: must match packaging labels and shipping documents.

- Moisture: value and (if provided) method reference.

- Defect summary (if provided): key defect categories aligned to your spec.

- Microbiology (program-dependent): aligned to your category requirements.

- Allergen statement: tree nut (almond) declaration aligned to labeling needs.

- Country of origin: for compliance and labeling workflows.

- Traceability identifiers: production/shipment identifiers to support recalls if needed.

If your customers require additional compliance documents (audit certificates, recall program summaries, food safety plan elements), request availability early. Documentation availability varies by program.

Receiving inspection checklist (buyer-friendly)

- Packaging integrity: no punctures, water damage, broken seals; correct labeling and lot codes.

- Odor check: clean, fresh almond aroma; no musty, rancid, or stale notes.

- Visual check: color uniformity aligned to your spec; minimal shell fragments and debris; no visible mold.

- Moisture verification: confirm against your target (especially in warm or humid seasons).

- Retains: keep a retained sample by lot for complaint investigation and shelf-life tracking.

QA tip: For sensitive products, require a defined sensory acceptance standard and keep a “golden lot” reference sample for comparison.

Questions to ask suppliers (procurement-focused)

Questions that map directly to spec outcomes

- What are typical moisture and defect ranges for this grade and crop year? Helps set realistic limits and buffers.

- What sorting and foreign material controls are used? Screening, aspiration, optical sorting (if used), metal controls.

- How is color managed and verified? Ask for how lots are classified and controlled.

- What storage and shipping practices protect quality? Helps reduce drift between ship and receipt.

- What documentation is available? COA, allergen, COO, traceability, and compliance docs as needed.

When to tighten specs (and when not to)

Tight specs protect quality but can reduce supply flexibility and raise costs. Tighten specs when your product is appearance- or flavor-sensitive, your shelf-life target is long, your destination lane is warm/long, or your customers have strict expectations. If your application is robust and inventory turns are fast, broader ranges may be acceptable without changing outcomes.

FAQ: almond kernel specs in industrial buying

What is the single most important field to define?

For many programs it is moisture, because it connects to storage stability and downstream variability. For premium visible applications, color may be equally critical. The “most important” field depends on your failure mode: sensory drift, appearance complaints, or foreign material risk.

Do defects always show up at receiving?

Not always. Some issues show up later in production (sensory drift, oxidation) or as a higher sorting burden. That’s why retained samples and defined sensory checks are valuable in sensitive programs.

How do I qualify a new supplier faster?

Combine documentation review (spec + COA + allergen/COO/traceability) with a receiving test: odor, visual defects, packaging integrity, moisture verification, and a small production trial if your application is sensitive.

Next step

If you share your application (kernels for snacks/bakery/confectionery/etc.), format, destination, and target shelf life, we can recommend practical moisture, defect, and color checkpoints and packaging options that match your program. Use Request a Quote or email info@almondsandwalnuts.com.

For sourcing, visit bulk almond products or browse the full products catalog.