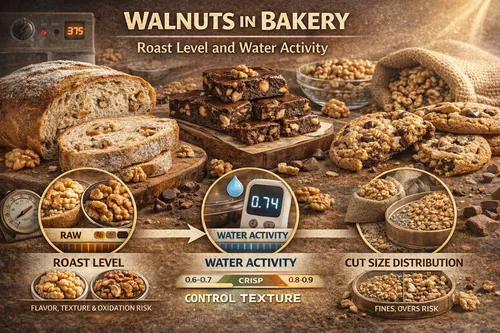

Walnuts in Bakery (Breads, Cookies, Brownies): Roast Level and Water Activity

Industrial guide to walnuts in bakery (breads, cookies, brownies): roast level selection, water activity (aw) control, and texture stability over shelf life. Covers raw vs roasted walnuts, cut size and inclusion behavior, aw strategy and moisture migration, processing and handling, packaging, specs/COA checkpoints, troubleshooting, and a buyer-ready RFQ template for bulk walnut bakery programs.

Previous: Walnut Butter in Bulk: Grinding, Particle Size, and Separation Management • Next: Walnuts in Confectionery: Chocolate Compatibility and Inclusion Preparation

Related: bulk walnut products • products catalog • request a quote

Quick takeaways for commercial bakeries:

1) Roast level is a flavor + texture decision, but it also changes oxidation risk and how walnuts behave in storage.

2) Water activity (aw) is about texture stability: it predicts whether inclusions stay crisp, soften, or contribute to staling over time.

3) For pieces and chopped walnuts, specify size distribution (fines/overs limits), not just “chopped.” That’s how you protect depositor performance and visual identity.

4) The most common failure mode is moisture migration + oxygen exposure. Solve it with aw targets, packaging, and realistic shelf-life validation.

Where this format fits in production

Walnuts show up in commercial bakery formulas for three reasons: sensory identity (nut flavor and aroma), texture contrast (bite, crunch, chew), and value signaling (visible inclusions increase premium perception). They also introduce real production variables: cut size distribution, moisture migration behavior, and oxidation sensitivity.

Common bakery applications for bulk walnuts

- Yeast breads and quick breads: inclusions in dough, toppings, or swirl/filling systems.

- Cookies: inclusions in high-fat doughs where spread and bite matter.

- Brownies and cake-like bars: inclusions in high-moisture matrices where softening is the main risk.

- Muffins: inclusions that must survive mixing and distribution without excessive fines.

- Toppings and enrobing: garnish applications where roasted notes and crunch are emphasized.

The “best” walnut format is the one that hits flavor and texture targets with the least line disruption—often determined by roast level, cut distribution, and packaging discipline.

Roast level selection: raw vs roasted vs custom roast

Roast level drives the customer’s first impression. But for industrial buyers, it also affects how the walnut behaves during mixing, baking, cooling, and storage. Think of roast as a system choice: flavor + texture + risk.

Raw walnuts (in-bake development)

- Best for: applications where the baking step develops aroma and you want a “fresh walnut” note without heavy roast.

- Operational benefit: fewer pre-roast steps and less handling of roasted product.

- Considerations: flavor outcome depends on your bake profile; some formulas may not deliver enough roast perception.

Roasted walnuts (pre-developed flavor)

- Best for: products where walnut aroma must be obvious at opening (premium cookies, toppings, artisan-style breads).

- Texture benefit: can deliver crispness and a cleaner “toasted” profile.

- Risk: roasted nuts can be more sensitive to oxygen exposure and warm staging; packaging matters more.

Light vs medium vs dark roast (how to think about it)

- Light roast: subtle toast, brighter nut notes; often used when you want walnuts to complement chocolate or spice without dominating.

- Medium roast: balanced toast and aroma; common choice for cookies and bakery toppings.

- Darker roast: stronger toast, deeper notes; can read as “premium” but can also feel more brittle and show more breakage in handling.

Buyer tip: Don’t specify roast by words alone. If roast is critical, define it by a measurable target (visual/color reference, sensory target, and any agreed process notes), and validate performance in your highest-sensitivity SKU.

Water activity (aw) basics for bakery inclusions

Water activity (aw) describes how “available” water is in a product. In bakery, aw often predicts shelf-life behavior better than moisture %. For walnut inclusions, aw is primarily a texture stability tool: it helps you predict whether inclusions stay crunchy or soften, and how the crumb evolves over time.

Why aw matters specifically for walnuts

- Texture preservation: walnuts can absorb moisture from a higher-aw matrix (brownies) and lose crispness.

- Moisture migration: if a walnut is drier (lower aw) than the crumb, moisture moves into the inclusion over time.

- Perceived freshness: soft walnuts can make a product feel stale even if the crumb is acceptable.

- Quality risk visibility: aw drift often explains “same recipe, different shelf-life outcome” problems.

Note: Your internal food safety program should define aw targets and validation steps appropriate for your product category. This article focuses on performance and texture.

Moisture migration: why walnuts soften (or your crumb dries)

Moisture migration is the tendency of water to move from a higher-aw region to a lower-aw region until equilibrium is reached. In a bakery product, that means water can move between the crumb, fillings, coatings, and inclusions. When walnuts are included, they participate in this “balancing act.”

Common migration scenarios

- Brownies: high-moisture matrix drives softening of inclusions over time if packaging and aw strategy aren’t optimized.

- Cookies: low-moisture cookie can sometimes pull moisture out of inclusions or cause uneven bite if distribution isn’t uniform.

- Sweet breads: gradients near fruit pieces or syrups can create localized softening around walnut clusters.

Practical levers to manage migration

- Choose the right cut size: smaller pieces equilibrate faster; larger pieces may preserve bite longer but can soften internally over time in high-aw matrices.

- Control bake + cool: under-baked centers or poor cooling can raise local aw and accelerate softening.

- Package quickly and correctly: delays between cooling and packaging allow moisture redistribution and oxidation exposure.

- Validate shelf life with real conditions: don’t validate only at ideal lab temperature—simulate distribution temperature cycling when relevant.

What to optimize by product type

Breads (yeast and quick breads)

In breads, walnuts are exposed to mixing energy and fermentation time (yeast products), then baking and cooling gradients. The main operational risks are breakage (creating fines that tint crumb and change eating texture) and uneven distribution. The main shelf-life risks are oxidation and localized moisture gradients, especially around inclusions and swirl zones.

- Best formats: halves or large pieces for premium visual identity; chopped when distribution uniformity is more important.

- Roast strategy: raw often works well because bake develops aroma; roasted can be used for premium aroma or toppings.

- aw focus: manage cooling and packaging to prevent condensation and to stabilize crumb over time.

Cookies

Cookies are often the most sensitive SKU to walnut variability because spread, bite, and visual distribution respond to changes in inclusion size and fines fraction. Walnut fines can act like a powder phase that subtly changes dough rheology, surface color, and spread behavior.

- Best formats: controlled chopped/pieces with defined fines and overs limits.

- Roast strategy: medium roast is common for “toasted” perception; raw works when cookie bake is robust and flavor is balanced with chocolate/spice.

- aw focus: manage package barrier and keep cookie moisture stable to avoid softening/crispness drift.

Brownies and cake-like bars

Brownies are high-moisture systems relative to many cookies. The main issue is that walnuts can lose crunch quickly due to moisture migration. Your strategy should focus on texture expectation: do you want walnuts to remain crunchy, or is a softer walnut acceptable?

- Best formats: larger inclusions for bite; smaller pieces for uniform distribution (but faster softening).

- Roast strategy: roasted can deliver stronger nut aroma at first bite; ensure packaging protects roasted flavor.

- aw focus: validate aw stability across shelf life and distribution; manage cooling and package sealing timing.

Cut size and distribution: inclusions, dosing, and breakage

In bulk walnut bakery programs, “pieces” and “chopped” are not precise enough by themselves. What you actually need is distribution control: limits on fines (too small), overs (too large), and a consistent center-of-mass particle size for your depositor or dough system.

Why distribution matters on high-speed lines

- Depositing and dosing: oversized pieces can clog nozzles or create weight variability.

- Visual identity: too many fines reduce “premium” appearance and can tint crumb.

- Texture consistency: too wide a distribution creates “some bites have nuts, some don’t.”

- Downstream processing: extra breakage during conveying or mixing creates more fines than you paid for.

Procurement translation: Specify “chopped” as a screen fraction target (or a defined size window) and include fines max and overs max. That’s how you buy line stability.

Process controls: mixing, staging, baking, cooling, and packaging

Walnuts are fragile inclusions. The plant controls that protect quality are mostly about minimizing unnecessary stress and minimizing exposure to oxygen and heat.

Mixing and inclusion addition

- Add late when possible: reduces breakage and fines generation.

- Control mixing energy: long or aggressive mixing can smear and fracture walnuts, especially in stiff doughs.

- Watch temperature: warm doughs can increase spread and accelerate oxidation of nut lipids.

Baking and cooling

- Even bake: under-baked centers keep aw high and accelerate moisture migration into walnuts.

- Controlled cooling: avoid condensation; condensation is an aw shock that can soften inclusions quickly.

- Time-to-pack discipline: longer exposure before packaging increases moisture redistribution and aroma loss.

Handling and sanitation

Walnuts are a tree nut ingredient. Align receiving, storage, line handling, and sanitation with your allergen program, including changeover and verification.

Shelf-life and oxidation: protecting walnut flavor

Walnut flavor stability is sensitive to oxygen exposure, temperature, and time. Roast level can increase the urgency of protection: roasted walnuts typically deliver high aroma up front, but they can lose sensory impact faster if packaging and storage are not aligned.

Practical shelf-life validation plan (buyer/operator friendly)

- Baseline sensory: day 0 (fresh pack), mid-life, end-of-life.

- Texture tracking: define what “crunchy enough” means by product type (cookie vs brownie).

- Distribution stress: validate under expected transit conditions (temperature cycling where applicable).

- Retained sample discipline: keep samples by lot and compare across lots when issues appear.

Packaging options for bulk programs

Bulk walnut bakery programs commonly use lined bags or cartons for kernels and cuts. Packaging needs to protect against oxygen exposure and moisture pickup while fitting your receiving constraints and internal handling methods.

Common packaging formats

- Lined cartons: good stackability and lot control; common for pieces and chopped formats.

- Multiwall bags with liners: common for industrial bakery use; confirm net weights and pallet configuration.

- Program-dependent options: some buyers request higher barrier liners when oxidation risk is high or storage duration is longer.

Receiving and storage notes

- Keep sealed until use: open-pack exposure accelerates oxidation and moisture pickup.

- Temperature stability matters: avoid warm staging and direct sunlight.

- Lot control: maintain clear lot segregation and FEFO practices (first-expire, first-out) when shelf life is critical.

Format and spec checkpoints buyers should confirm

The best spec sheet is the one that matches your real risks and your real receiving tests. For bakery walnut programs, these checkpoints are commonly used:

Core checkpoints

- Format: halves/kernels vs pieces vs chopped (define size distribution if not whole).

- Moisture: target and method; ensure consistency across lots.

- Color/grade: define what “acceptable” means for your product appearance and customer expectations.

- Defect limits: align to your QA and finished-product tolerance.

- Foreign material controls: understand how the program prevents and verifies FM control.

- Micro requirements: aligned to your category and internal program.

Roasted walnut checkpoints (if applicable)

- Roast profile target: light/medium/dark (define by reference), and sensory acceptance.

- Handling expectations: how roasted product is protected during storage and transit.

- Breakage tolerance: roasted product can be more brittle; specify fines limits if line-sensitive.

Troubleshooting guide

| Problem | Likely drivers | First checks |

|---|---|---|

| Walnuts soften in brownies | High aw matrix, slow cooling, long pre-pack hold, package barrier too low | Cooling time-to-pack, packaging integrity, shelf-life validation under distribution conditions |

| Cookie spread drift | Cut size variation, fines fraction change, dough temp/rest changes | Pieces/chopped distribution specs, fines/overs limits, dough temperature at deposit |

| Gritty or dusty bite | Excess fines from supply or internal breakage | Incoming sieve check, mixing energy, conveying stress points |

| Rancid/off notes | Oxidation from warm staging or oxygen exposure; roasted nuts more sensitive | Storage conditions, packaging barrier, lot age, retained sample sensory |

| Uneven distribution | Poor inclusion dispersion, clumping, inconsistent cut size | Inclusion addition timing, mixing order, size distribution spec |

How to request a quote with fewer back-and-forths

To get an accurate quote quickly, send a buyer-ready message that includes application, format, roast target, and the distribution constraints that keep your line stable.

RFQ template (copy/paste):

Product: Walnuts for bakery (breads/cookies/brownies)

Format: halves/kernels / pieces / chopped

Roast: raw / roasted (light/medium/dark) • sensory target notes: [ ]

Cut/size distribution (for pieces/chopped): target [ ] • fines max %: [ ] • overs max %: [ ]

Grade/color targets: [ ] • substitution rules (if allowed): [ ]

Moisture target/range: [ ]

Defect limits / foreign material expectations: [ ]

Micro requirements: [targets appropriate for your category]

Packaging: cartons/bags + liners • net weight per unit: [ ] • pallet configuration: [ ]

First order volume: [lbs/kg] • Annual forecast: [lbs/kg]

Destination: [city, state/country] • Timeline: sample by [date], first ship by [date]

Documentation needed: COA, allergen statement, country of origin, other: [ ]

Notes: shelf-life target, packaging barrier expectations, receiving constraints, any customer-specific requirements: [ ]

FAQ

How do I stop walnuts from getting soft in brownies?

In brownies, softening is usually moisture migration plus packaging timing/barrier. Improve cooling discipline (avoid condensation), reduce time-to-pack, validate packaging barrier integrity, and confirm your shelf-life outcome under realistic distribution conditions.

Does roasting walnuts reduce moisture migration problems?

Roasting changes texture and flavor, but moisture migration is mainly driven by aw differences between inclusion and matrix and the storage environment. Roasting can make walnuts feel crisp at day 0, but without aw and packaging alignment they can still soften over time in high-moisture products.

What’s the most important spec for chopped walnuts on a cookie line?

Size distribution (including fines/overs limits) is often the most operationally important because it affects dosing, appearance, and dough behavior. Pair that with moisture and clear defect/foreign material controls.

Next step

If you share your bakery application (bread/cookies/brownies), roast preference (raw vs roasted), cut size target, and shelf-life goals, we can help confirm common spec targets, packaging options, and the fastest supply lane for your bulk walnut program. Use Request a Quote or email info@almondsandwalnuts.com.