Drying Targets for Almond Kernels: Moisture, Storage Safety, and Quality

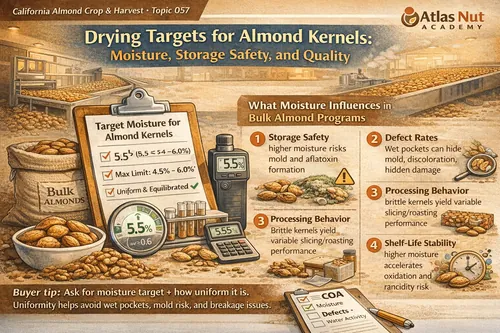

Drying is the bridge between harvest and storage stability. If kernels are held too wet, mold risk and quality loss rise quickly. If they’re pushed too dry (or dried unevenly), you can create brittle texture, higher breakage, and inconsistent performance. This guide shows what buyers should ask for and how moisture targets connect to COA, storage safety, and shelf-life outcomes.

Previous: Hulling and Shelling Almonds: How Post-Harvest Steps Influence Quality • Next: Sorting, Sizing, and Defect Removal: How Almond Grades Are Built

Related: bulk almond products • products catalog • request a quote

Why drying targets matter to buyers

Moisture isn’t just a “QA number.” It drives how almonds behave in storage and in your plant:

- Storage safety: higher moisture increases mold risk and accelerates quality loss.

- Defect outcomes: wet pockets and uneven drying can correlate with hidden damage and higher rejects at receiving.

- Line performance: moisture affects brittleness, breakage, slicing, roasting consistency, and inclusion integrity.

- Shelf-life: drying and storage conditions together influence rancidity risk and flavor stability over time.

Buyer framing: ask for “moisture target + how uniform it is,” and confirm how the lot was equilibrated/handled before packing. Uniformity often matters as much as the average.

Field-to-warehouse context: where drying sits in the flow

In a typical program: harvest operations → drying (yard or forced-air systems) → hulling/shelling → sorting/grading → warehousing. Drying is the point where a weather-driven harvest becomes a storage-ready ingredient.

Moisture targets buyers should specify

Your exact target depends on product form (inshell vs kernel), intended storage time, and destination logistics. Most industrial purchasing programs specify a kernel moisture target and a maximum limit, then verify via COA and receiving checks.

- Target moisture: set a clear aim point for your application (e.g., “moisture target X%”).

- Maximum limit: include a hard ceiling (“not to exceed Y%”).

- Uniformity expectation: ask how the supplier manages lot equilibration and avoids wet pockets.

- Test method: confirm the moisture test method and where it’s measured (in-process vs final packed lot).

If your team also uses water activity (aw) internally for risk screening, request it as a supplemental checkpoint—but keep moisture as the commercial spec anchor unless your category requires aw.

Common failure modes (and how specs prevent them)

- Over-wet lots: higher mold risk, off-odors, shorter shelf life; avoid with clear max moisture + storage requirements.

- Uneven drying: wet pockets that pass an average test but fail in storage; mitigate by asking about equilibration and lot blending controls.

- Over-drying / brittleness: more breakage, higher fines, inconsistent slicing; prevent by specifying a target (not only a max) and aligning on handling expectations.

- Re-wetting during logistics: moisture pickup from high humidity or poor packaging; prevent by matching packaging and warehouse controls to transit time and climate.

Quality checkpoints that connect to procurement specs

Moisture interacts with other receiving checks and COA fields. A practical buyer checklist:

- Moisture: target + max limit (and method).

- Defects: insect damage, mold-related defects, discoloration, foreign material controls.

- Grade/size: align grade definition to your use case (whole, diced, sliced, etc.).

- Microbiology: confirm requirements based on your category and any kill-step assumptions.

- Sensory: baseline aroma/flavor expectations to catch storage issues early.

Storage, oxidation, and logistics

Even with good drying, storage conditions drive shelf-life performance. For longer holding times or warm destinations, align:

- Warehouse conditions: temperature and humidity management appropriate for your shelf-life target.

- Packaging: liners/seals that protect against humidity swings and oxygen exposure (program-dependent).

- Transit time: shipping lane and seasonality (summer heat exposure) may require stronger controls.

How to use this in buying decisions

When qualifying suppliers or approving a new crop-year lot, use drying targets as a risk screen:

- Align moisture target with your storage time and finished-product shelf-life needs.

- Ask how the supplier ensures moisture uniformity across the lot (not just an average).

- Confirm receiving test plan (your method vs supplier method) to avoid disputes.

- For sensitive SKUs (sliced, blanched, premium whole), tighten the target and handling controls to reduce breakage and rejects.

Next step

If you share your almond format (whole, sliced, diced, meal/flour) plus your storage duration and destination, we can recommend a practical moisture target + documentation checklist that reduces storage risk and receiving surprises. Use Request a Quote or email info@almondsandwalnuts.com.