Cold-Pressed Almond Oil for Food Applications: Flavor Profile, Smoke Point, and QA

Cold-pressed (often “virgin”) almond oil can be purchased either for subtle almond character or for a “premium, minimally processed” positioning. Unlike refined almond oil, cold-pressed lots can vary more in aroma, color, and smoke behavior due to natural minor components and differences in pressing and filtration. This guide outlines buyer-ready checkpoints: flavor profile, smoke point context, and QA gates that protect consistency and shelf-life at scale.

Previous: Defatted Almond Protein Powder for Nutrition Systems: Formulation and Handling • Next: Refined vs Crude Almond Oil: Use Cases, Odor/Color, and Documentation

Related: bulk almond products • products catalog • request a quote

Where this format fits in production

Cold-pressed almond oil is typically used where a clean, mild nut note or a “minimally processed” claim has value. The best-fit applications are those that protect aroma and avoid extended high-heat exposure.

Best-fit uses

- Dressings and sauces: subtle nutty roundness; often used in premium emulsions and vinaigrettes.

- Finishing oil: drizzles for salads, vegetables, soups (post-cook), and plated applications.

- Bakery and confectionery: select formulations where almond aroma is desired without particulates.

- Specialty snack systems: light flavor carrier for seasonings in some programs (process dependent).

- Blends: used as a character note blended with neutral oils for cost or stability.

Watch-outs

- High-heat frying: cold-pressed oils can be inconsistent at high heat; refined oils are usually the better fit.

- Warm storage / open tanks: oxidation accelerates quickly with oxygen and heat exposure.

- Filtration variability: haze or sediment may be acceptable in “natural” programs but can disrupt dosing and appearance.

Practical rule: if you’re buying cold-pressed for sensory, treat the program like a premium aroma ingredient—pair sensory gates with oxidation metrics and packaging that matches your inventory turns.

Flavor profile: what “good” cold-pressed almond oil looks like

Cold-pressed almond oil is usually mild compared to walnut or sesame oils. That mildness is the point—but it also means oxidation or stale notes can show up as “flatness” or a dull finish before they look dramatic.

Typical positive descriptors

- Aroma: clean, light almond/nut notes, gentle sweetness, minimal grassiness

- Flavor: mild nutty roundness, smooth mouthfeel, low bitterness

- Finish: short-to-moderate, clean finish without harshness

Common rejection notes (put these in your spec)

- Painty / varnish / stale: oxidation progression

- Cardboard / dull aroma: loss of fresh top-notes (often early warning)

- Harsh / prickly finish: secondary oxidation compounds rising

- Musty / storage-like: raw-material or handling contamination

Buyer tip: Because almond oil is subtle, evaluate it in your finished matrix (e.g., dressing base) during qualification—not only neat.

Smoke point: what to know (and how to spec it without surprises)

Smoke point is influenced by refining level, free fatty acids, and minor compounds. Cold-pressed oils can vary more lot-to-lot than refined oils. If smoke behavior is critical, treat “smoke point” as a validated performance requirement, not a marketing line.

Practical guidance for buyers

- For high-heat processes: consider specifying refined almond oil instead of cold-pressed.

- If you must use cold-pressed at heat: request a smoke point value on COA (method as agreed), and run a short plant trial under your exact conditions.

- Control FFA: higher FFA can reduce smoke point; include FFA as a gate when smoke behavior matters.

- Don’t ignore stability: an oil can “smoke acceptably” on day one but degrade quickly under repeated heat cycles.

If your use case is sauté or baking with meaningful heat exposure, specify the performance target (temperature + duration + reuse) and qualify oil against that—not just a single smoke point number.

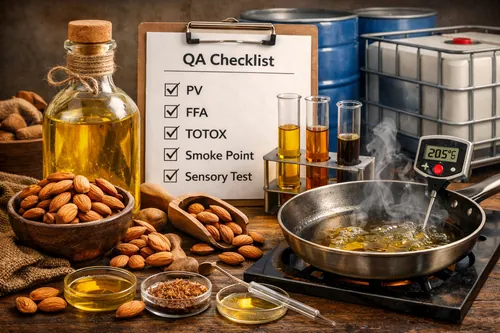

QA checks: what to test and what to put on the COA

A strong cold-pressed almond oil program combines sensory gating with oxidation indicators. Choose a tier aligned to shelf-life expectations, distribution lanes, and how long containers stay open in your plant.

Tier 1 (most common): buyer-ready basics

- Sensory evaluation: aroma + flavor against your acceptance language (and ideally a retained reference)

- Peroxide value (PV): primary oxidation screening

- Free fatty acids (FFA): hydrolytic breakdown + smoke behavior relevance

- Color: acceptable window (especially for light dressings)

- Clarity / insolubles: specify if dosing, appearance, or sediment control matters

Tier 2 (shelf-life sensitive): better prediction of future performance

- Anisidine value (AV): secondary oxidation compounds

- TOTOX: combined index (from PV and AV) for comparing lots and drift over time

- Moisture & volatiles: helps reduce hydrolysis risk and supports stability

Tier 3 (program-dependent)

- Smoke point: include if heat performance is critical (agree method and reporting)

- Residues/contaminants: customer or export-lane dependent

- Fatty acid profile / authenticity checks: optional for verification in certain markets

- Allergen handling statement: almond/tree-nut declaration and cross-contact language needed by your customers

Buyer tip: PV alone can miss “trending” lots. Pair sensory + PV, and add AV/TOTOX when shelf-life is critical or transit is long.

Shelf-life and oxidation control

Almond oil stability is driven by oxygen, temperature, light, and time. Cold-pressed programs typically require tighter control because minor components and handling differences can accelerate flavor drift.

- Storage: cool, stable conditions; avoid warm warehouses and temperature cycling.

- Handling: minimize open time; reseal containers; avoid long-open intermediate tanks.

- Receiving checks: quick sensory check on arrival prevents downstream flavor defects.

- Inventory turns: align pack size to consumption rate (big tote + slow usage = higher risk).

Packaging options for bulk programs

Packaging is both logistics and shelf-life control. Match packaging to your receiving equipment and how fast you consume oil after opening.

- Pails: good for smaller runs and faster open/use cycles.

- Drums: common for medium volume; confirm seals, food-grade lining, and dispensing method.

- IBCs / totes: best for high-throughput plants with closed transfer systems and strong oxygen/temperature control.

Share early: receiving setup (pump/fittings), max pallet height, warehouse temperature profile, and whether you need re-pack.

Specs checklist (quote-ready)

If you have a spec sheet, send it. If not, this checklist usually gets to a quote quickly:

- Product: Cold-pressed (virgin) almond oil

- End use: finishing/dressing/sauce/bakery/heat use (specify temperatures and dwell time if heated)

- Sensory target: clean, mild almond character; rejection notes list

- QA gates: PV + FFA + sensory (add AV/TOTOX + moisture/volatiles if shelf-life sensitive; add smoke point if heat-critical)

- Appearance: color window; clarity/insolubles; sediment tolerance

- Packaging: pails/drums/IBCs + discharge fitting needs

- Volume: first order + forecast; delivery cadence

- Destination: city/state/country + required delivery window

- Documentation: COA, traceability, COO, allergen statements, certifications if required

If smoke behavior matters, include: “critical-to-quality = smoke performance at ___°C for ___ minutes” plus your reuse/hold conditions. That’s the fastest way to avoid a mismatch.

FAQ

Is cold-pressed almond oil a good fryer oil?

Usually not. If high-heat stability and cost-efficiency matter, refined oils are typically a better fit. Cold-pressed oils are commonly purchased for aroma and premium positioning.

Which tests best predict rancidity risk?

Sensory is the fastest screen. PV helps detect primary oxidation; AV/TOTOX improve prediction of secondary oxidation drift. FFA and moisture/volatiles help catch hydrolysis risk and handling problems.

Why can cold-pressed almond oil look hazy?

Haze or settling can result from natural minor components or fine solids if filtration is light. If clarity matters for your product, specify filtration/insolubles and sediment tolerance.

Next step

Share your application, heat exposure (if any), and your sensory target. We’ll recommend a practical QA gate set and packaging format, then align documentation and the best supply lane. Use Request a Quote or email info@almondsandwalnuts.com.