California Walnut Varieties and Grades: Chandler and Other Programs

“Chandler” is the variety name buyers hear most—but walnut procurement is really about the intersection of cultivar (variety), grade (halves vs pieces and defect tolerances), and color (extra light through amber). If you’re buying bulk walnuts for bakery, confectionery, snacks, cereal/granola, dairy-alternative bases, or foodservice, understanding this trio helps you spec correctly, protect sensory quality, and avoid price surprises.

Previous: Traceability and Crop-Year Planning for Almond Buyers: Forecasting and Programs • Next: Walnut Orchard Management Basics: What Influences Kernel Quality

Related: bulk walnut products • products catalog • request a quote

Quick definitions: variety vs grade vs color

Walnut conversations get messy because people use “grade” to mean different things. In industrial buying, it helps to separate three layers:

Variety (cultivar)

The orchard type (e.g., Chandler, Howard, Tulare). Variety influences kernel size, shelling behavior, typical kernel color range, harvest timing, and how consistently a program can deliver halves.

Grade (cuts + tolerances)

How the product is sorted and sold (halves, large pieces, medium pieces, small pieces, meal) plus defect tolerances. Grade is where most cost differences show up for manufacturing.

Color (appearance tier)

The kernel color band you’re buying (extra light / light / light amber / amber). Color affects visual quality and perceived “freshness” in many finished products—especially bakery and confectionery.

Buyer rule-of-thumb: if your finished product shows the walnut (toppings, inclusions, clear packaging), specify color + cut. If your product hides the walnut (brown batters, spice systems), prioritize cut + defect control over premium color.

Why Chandler is common—and why “Chandler-only” may not be the right spec

Chandler is widely used in commercial programs because it typically supports strong kernel quality and consistent industrial performance. That said, most large supply lanes are built around grade and color targets, not a single variety name. In practical buying, “Chandler program” often means:

- Consistent output mix: predictable balance of halves and pieces for packing lines.

- Color intent: a program aimed at higher color tiers (when the crop and storage support it).

- Uniformity: fewer surprises in size distribution and shelling behavior vs mixed-orchard pools.

If you write “Chandler only” into a spec, you can narrow your supplier options and potentially increase cost—without improving your finished product if your real requirement is actually “light color halves” or “clean medium pieces.”

Practical alternative: specify what you need functionally (cut + color + defect thresholds) and treat variety as preferred unless your process truly depends on it.

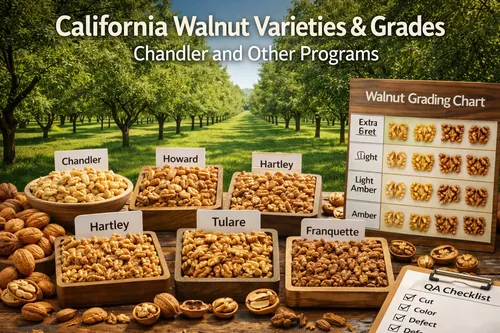

Common California walnut varieties buyers may encounter

California programs may include multiple cultivars depending on orchard economics, harvest windows, and processor programs. The exact sensory and shelling behavior can vary by crop year and handling, but buyers can use these profiles to ask better questions.

Chandler

- How buyers use it: a “reference” variety for many bulk walnut programs.

- Why it matters: often associated with a stable quality lane for halves and light-to-medium color targets (program dependent).

- Procurement note: if you need premium visual performance, ask for the targeted color band and how it’s protected in storage.

Howard and Tulare

- How buyers encounter them: as part of commercial programs, sometimes alongside Chandler.

- Why it matters: may differ in typical size distribution, halves yield, and color stability depending on crop and handling.

- Procurement note: if you’re sensitive to “visible piece size,” confirm the screen-size distribution of the grade you’re buying.

Hartley and Franquette (and other legacy types)

- How buyers encounter them: in certain orchard pools and traditional programs.

- Why it matters: depending on program, may contribute different kernel shapes/sizes and a different halves/pieces balance.

- Procurement note: if you’re building a very tight inclusion spec, validate a sample/retention lot to confirm consistency.

Serr, Vina, and mixed-orchard pools

- How buyers encounter them: more often as part of mixed supply pools where cut and color targets drive the offer.

- Why it matters: mixed pools can be cost-effective but may show more variability in particle distribution if your spec is loose.

- Procurement note: if you’re cost-optimizing, shift control to cut distribution + defect limits, and be realistic about color.

If your line settings are sensitive (depositor, inclusion feeder, topping applicator), ask suppliers to describe how they manage run-to-run cut distribution and color sorting—that’s often more actionable than a single cultivar name.

How “walnut grades” show up in bulk buying

For most manufacturers, “grade” is a combination of: cut type (halves vs pieces), size distribution, and defect tolerances. This is where performance and cost connect directly.

Cut types: halves vs pieces vs meal

- Halves: highest visual impact; common for toppings, premium inclusions, and retail-style mixes.

- Large pieces: strong visual inclusion with better cost efficiency than halves in many SKUs.

- Medium/small pieces: useful when distribution and coverage matter more than “show” (bars, granola, bakery inclusions).

- Meal/fine pieces: functional use in batters, coatings, fillings, and bases where visual identity is not required.

What “grade” changes operationally

- Feeding consistency: broader distributions can bridge in hoppers or segregate in vibration-heavy handling.

- Inclusion coverage: smaller pieces often deliver more uniform coverage per pound in bars/cereal.

- Finished texture: halves/large pieces add “chunk” and crunch; smaller pieces distribute texture more evenly.

- Breakage sensitivity: aggressive conveying and long drops can create fines—especially in halves programs.

If your product spec says “halves,” define what breakage is acceptable at receiving. A realistic program accounts for handling—especially for exports and long transit.

Color categories: what buyers should specify (and when it matters)

Walnut kernel color is one of the strongest drivers of perceived quality and price. In many programs, color is described in tiers from lighter to darker. Your best buying move is to choose the lightest tier that actually impacts your finished product.

When color matters most

- Light bakery: shortbread, cakes, pastries, fillings where dark specks are visually obvious.

- Confectionery: enrobed nuts, brittle, praline-style applications where contrast matters.

- Retail-style mixes: transparent packs and premium positioning.

- Foodservice garnish: salads and plated items where the walnut is a visual element.

When color is usually less critical

- Chocolate, spice, or caramel systems: the matrix visually dominates.

- Brown batters: many cookies, brownies, breads where darker kernels are not a defect.

- Ground systems: meal/flour use where the walnut is not visible as pieces.

Procurement tip: if you can relax color by one tier without changing your consumer experience, you often unlock more supply lanes and reduce risk during tight markets.

Defect language buyers should align early

“Defects” is where buyer expectations often diverge from what a supplier thought was acceptable. Define your defect concerns explicitly, especially if your product is premium or if you have strict customer audits.

Common defect buckets

- Foreign material: shell pieces, wood, stones, field debris (control depends on sorting and inspection steps).

- Insect damage: visual defects, holes, or compromised kernels (program and crop-year dependent).

- Mold/quality defects: off-appearance or off-odors (critical for high-sensitivity brands).

- Shrivel/shrunken kernels: impacts bite, appearance, and consumer perception.

- Rancidity risk drivers: oxidation notes, stale flavor, or “painty” aromas (often linked to storage and oxygen exposure).

Receiving gate idea: build a quick check around appearance + odor. Catching an oxidation issue at receiving is dramatically cheaper than discovering it after production.

How variety and handling influence halves yield and breakage

Buyers often ask for “more halves” without considering what determines halves output. Halves yield is influenced by:

- Kernel shape and shelling behavior: some programs naturally produce more intact halves depending on orchard mix and shelling settings.

- Moisture and conditioning: overly dry kernels can become brittle; poor conditioning can increase breakage.

- Mechanical handling: long drops, hard transfers, and aggressive conveying break halves into smaller pieces.

- Rework loops: multiple passes through equipment tend to increase fines and reduce “clean halves” percentage.

The practical way to buy halves is not just “halves only,” but also: breakage tolerance, acceptable fines, and the packaging/handling method that protects the cut.

QA and documentation checkpoints for bulk walnut programs

A solid walnut program combines in-process controls at the processor and buyer-side receiving checks. Your exact plan depends on your end use, risk posture, and any customer audit requirements.

Common COA-style items

- Moisture: a key driver of texture, brittleness, and storage stability.

- Cut/grade declaration: halves vs pieces, plus any screen-size distribution if your line is sensitive.

- Color declaration: specify the intended color band when appearance matters.

- Defect/foreign material statement: aligned to your internal spec and any customer standards.

- Micro / food safety documentation: depends on product category and customer requirements.

- Traceability: lot IDs, pack dates, crop-year (if applicable), and country of origin statement.

Buyer-side receiving checks that prevent surprises

- Visual: color consistency, shell fragments, excessive fines, insect damage.

- Odor/sensory: quick sniff test for oxidation/off-notes (especially for premium products).

- Handling behavior: flow in hoppers (for pieces), breakage behavior (for halves), dustiness/fines (for long conveyors).

- Pack integrity: liner seals, case condition, pallet stability—small issues here can create quality drift in your warehouse.

Storage and logistics: protecting color and flavor after purchase

Even a well-sorted lot can lose quality if storage conditions are not aligned with shelf-life expectations. The main risk drivers are oxygen exposure, temperature, humidity, and time.

- Temperature stability: avoid warm storage and repeated temperature cycling (which can accelerate quality drift).

- Open-time management: minimize time in open bins; reseal partial cases quickly to reduce oxygen exposure.

- FIFO discipline: rotate lots; don’t let a “backup pallet” become a long-dwell quality risk.

- Transit planning: export lanes and hot climates amplify risk—choose packaging and timelines accordingly.

If your product is shelf-life sensitive, ask early about packaging options that reduce oxygen exposure, and share your destination climate profile so the program can match the risk level.

Packaging options for bulk walnuts

Packaging should match your receiving method (dock equipment, pallet constraints), your inventory turns, and your oxidation risk posture. Bulk walnut programs commonly ship in lined cartons or bags, with optional upgrades depending on program and destination.

- Lined cartons / bags: common for halves and pieces; confirm case pack and liner type.

- Bulk bags: efficient for high-volume pieces programs; confirm handling equipment and dust control needs.

- Program upgrades (where available): higher barrier liners or other oxygen-management options for long shelf-life or export lanes.

- Pallet configuration: confirm maximum height, wrap requirements, and any special racking constraints.

Share your receiving constraints early (pallet footprint, maximum stack height, dock limitations, re-pack needs). Packaging mismatches are a common source of delays.

How to write a quote-ready walnut spec (without over-specifying)

The fastest path to the right offer is to specify what drives your finished product and your line performance. Use variety as a preference when it truly matters—but don’t use it as a proxy for cut/color/defect requirements.

Core spec items (most programs)

- Product form: walnut halves, large pieces, medium pieces, small pieces, meal

- Color target: specify the required color band if appearance is critical; otherwise state “standard manufacturing color acceptable” (or your internal language)

- Defect limits: foreign material tolerance, shell pieces expectation, and any critical defect exclusions

- Moisture target: align to your texture and storage expectations

- Micro / food safety: requirements based on your category and customers

- Documentation: COA, traceability, COO, certifications if required

Add these when line performance is sensitive

- Cut distribution: screen-size distribution or a practical description (“tight medium pieces; minimal fines”)

- Breakage tolerance: for halves programs (what % breakage is acceptable at receiving)

- Handling notes: hopper/auger feeding, dust control constraints, conveyor drops

- Application: topping vs inclusion vs grind; the supplier can optimize the offer if they know the use case

If you’re switching suppliers, validate with a short plant trial. Small shifts in pieces distribution can change inclusion weights, visual coverage, and feeder settings.

Specs checklist (quote-ready)

If you have a spec sheet, send it. If not, this checklist usually gets to a quote with fewer back-and-forths:

- Product: Bulk walnuts (halves / pieces / meal)

- Cut/grade target: preferred cut type + any cut distribution expectations (especially for pieces)

- Color target: required band if appearance matters; otherwise state your tolerance

- Defect limits: foreign material, shell pieces, insect damage tolerance, shrivel/shrunken tolerance

- Moisture: target range and texture expectations

- Micro / food safety: requirements for your category

- Packaging: cartons/bags; case pack; pallet constraints; receiving equipment

- Volume: first order + forecast; delivery cadence

- Destination: city/state/country; required delivery window; export documentation needs (if any)

- Documentation: COA, traceability, COO, certifications if required

- Application: bakery/confectionery/snacks/cereal/foodservice; whether walnuts are visible (drives color priority)

Next step

Share your application (bakery inclusion, topping, confectionery, snack mix, cereal/granola, or ingredient grinding) and your target cut + color outcome. We’ll confirm practical spec targets, packaging options, and the fastest supply lane for your bulk walnut program. Use Request a Quote or email info@almondsandwalnuts.com.