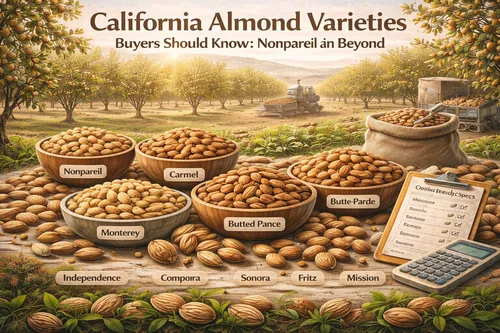

California Almond Varieties Buyers Should Know: Nonpareil and Beyond

“Nonpareil” is the variety name buyers hear most—but industrial almond procurement is really about matching variety + grade/size + defect/moisture targets to your process. Variety choice affects appearance, blanchability, roasting behavior, texture, and (in some cases) supply lane stability. This guide covers what buyers should know about Nonpareil and common companion varieties—so you can spec the right product without overpaying or over-constraining supply.

Previous: How to Request a Quote for Bulk Walnut Products: The Spec Sheet Buyers Use • Next: Almond Bloom, Pollination, and Weather Risk: Why Crop Timing Matters

Related: bulk almond products • products catalog • request a quote

Quick definitions: variety vs grade vs size

Almond buying gets confusing because “grade” can mean different things in different plants. In bulk procurement, it helps to separate three layers:

Variety (cultivar)

The orchard type (Nonpareil, Carmel, Monterey, Butte/Padre, Independence, Sonora, etc.). Variety influences kernel shape, blanchability, typical color tone, texture, and how it behaves during roasting and processing.

Grade / quality tier

The quality program and tolerances (sound kernels, defect limits, foreign material controls, and any micro requirements). This is where many price differences show up for industrial buyers.

Size / screen count

How kernels are sized for consistent appearance and processing (especially for snack packs, confectionery, and roasting lines). Size impacts roast uniformity, coating pickup, and finished visual quality.

Buyer tip: don’t buy “Nonpareil” as a shortcut for quality. If your real need is uniform roast + low defects, specify size + defect/moisture targets and treat variety as “preferred” unless your application truly depends on it.

Why Nonpareil is the reference variety (and when it matters)

Nonpareil is often the “reference” in California almond buying because many programs use it for premium visual uses: snack almonds, blanched products, and roasted formats where appearance and consistency matter. In practice, “Nonpareil program” usually implies:

- Appearance-driven use: kernels that tend to present well in visible applications.

- Blanching suitability: commonly used where blanch yield and skin removal performance matter.

- Roast uniformity intent: when paired with tight sizing, it supports consistent roasting and coating lines.

But if your almond is not visible (ground meal/flour, paste/butter, inclusions in dark systems), paying for a strict “Nonpareil-only” spec often adds cost without improving your finished product.

Common California almond varieties buyers should recognize

Most industrial supply lanes use a mix of varieties depending on application and cost targets. Exact behavior varies by crop year and handling, but these are useful “buyer mental models.”

Nonpareil

- Best fit: premium visible applications, blanching, roast-and-salt programs, high-spec snack and confectionery.

- Procurement note: if you need tight visual consistency, lock in size counts and defect tolerances, not just the variety name.

Carmel (common companion variety)

- Best fit: roasted, diced/sliced applications, and many manufacturing programs where you still want good appearance but at better value.

- Procurement note: useful when you want a “premium-ish” look without the tightest Nonpareil constraint.

Monterey

- Best fit: roasting lines and many manufacturing programs; can be attractive for cost-optimized supply lanes.

- Procurement note: if you’re coating or seasoning, ask for size distribution control to protect roast uniformity and pickup.

Butte/Padre (often referenced together)

- Best fit: ingredient manufacturing (pieces, meal, flour), paste/butter, and systems where the almond is not primarily a visual element.

- Procurement note: shift your focus to defect limits, moisture target, and micro requirements—these drive performance in ingredient uses.

Independence and other newer/mixed-orchard pools

- Best fit: many cost-effective lanes when your spec is defined by functionality (size/defect/moisture) rather than a single cultivar.

- Procurement note: if you can accept “approved varieties,” you often unlock more supply flexibility in tight markets.

Sonora / Fritz / Mission (and other legacy types)

- Best fit: program-dependent; sometimes used for specific textures, inclusions, or value lanes.

- Procurement note: validate with a sample/retention lot if your process is sensitive—kernel shape/texture differences can matter in specialty products.

If you’re switching suppliers, run a short plant trial. Small shifts in sizing and defect profile can change roast time, coating pickup, and yield.

Where variety choice shows up in production

Blanched almonds and sliced/diced formats

- What matters: blanch yield (skin removal), kernel integrity, uniform color after blanching.

- How to spec: variety preference (often Nonpareil/Carmel), plus tight sizing and defect limits.

Roasted / seasoned snack almonds

- What matters: size consistency for roast uniformity, surface condition for seasoning pickup, low defects for consumer perception.

- How to spec: size count + defect limits + moisture target; variety can be “preferred” unless branding demands Nonpareil.

Bakery and inclusions

- What matters: cut (whole/sliced/diced), color/appearance (if visible), and defect control.

- How to spec: focus on cut specification and defect limits; variety matters most for premium visible inclusions.

Ingredient systems (meal, flour, butter/paste)

- What matters: moisture control, oxidation management, and micro/documentation alignment.

- How to spec: variety is usually secondary; functionality and QA specs dominate.

Quality checkpoints that connect to procurement specs

Variety matters, but most “wins and losses” in almond buying come from the basics:

- Moisture target: stability, texture, and storage risk control.

- Defect limits: insect damage, foreign material, mold risk indicators, and visual defects.

- Size distribution: critical for roasting, coating, and premium visible applications.

- Micro requirements: align to category/customer requirements (especially for ready-to-eat uses).

- Packaging integrity: liner/barrier expectations, pallet stability, and protection during transit.

- Traceability: lot ID, pack date, crop-year context (if needed), and COO documentation.

If your finished product is shelf-life sensitive, treat almonds like an oil-containing ingredient: oxygen exposure + heat + time drive flavor drift. Packaging and warehouse discipline matter.

Storage, oxidation, and logistics (the part buyers underestimate)

Even great crop-year quality can be lost with poor storage. Key levers: temperature stability, oxygen exposure, humidity control, and FIFO discipline.

- Storage: cool and stable; avoid warm warehouses and temperature cycling.

- Handling: minimize open-bin time; reseal partial cases quickly.

- Receiving sensory gate: quick odor check can prevent downstream rancidity surprises.

- Transit planning: long routes and hot climates increase risk—match packaging and timelines accordingly.

Packaging options for bulk almond programs

Bulk almonds typically ship in lined cartons or bags; the best choice depends on your receiving method, plant environment, and inventory turns.

- Lined cartons/bags: common for kernels and cuts; confirm liner expectations if shelf-life is critical.

- Pallet constraints: share max height, footprint, and dock equipment constraints early.

- Re-pack needs: if you re-pack or blend, confirm liner compatibility and dust control needs (for cuts/meal).

Specs checklist (quote-ready)

If you have a spec sheet, send it. If not, these details typically get to a quote quickly:

- Product form: whole kernels / sliced / diced / slivered / meal / flour / butter / oil

- Variety: Nonpareil preferred / approved varieties / specific list (only if truly required)

- Size target: count/screen range (especially for roasting or premium visual SKUs)

- Moisture target: stability and texture expectations

- Defect limits: foreign material, insect damage, mold risk indicators, visual defects

- Micro requirements: as applicable to your category

- Packaging: cartons/bags; pallet constraints; receiving equipment

- Volume: first order + forecast; delivery cadence

- Destination: city/state/country + required delivery window

- Documentation: COA, traceability, COO, certifications if required

- Application: snack/roasting, bakery inclusion, confectionery, ingredient grinding, dairy-alternative base, etc.

If line performance is sensitive, include: “critical-to-quality = size uniformity, defect control, and shelf-life flavor stability” so the program can target tighter controls.

Next step

Share your end application (snack, blanch/slice, roast/season, bakery inclusion, ingredient milling) and what matters most (appearance, roast uniformity, defect limits, shelf life). We can recommend whether Nonpareil is truly necessary—or whether a broader approved-varieties spec hits the same outcome with a stronger supply lane. Use Request a Quote or email info@almondsandwalnuts.com.